- HOME

- Applications

- Blog

- The Ultimate Guide to SMA Plug Connector Types and Specifications

The Ultimate Guide to SMA Plug Connector Types and Specifications

25-05-28

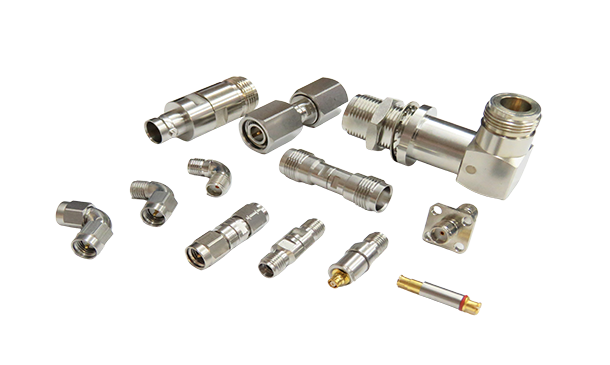

SMA (Subminiature version A) male connectors have become a key component in modern wireless communications, test equipment, military applications, 5G technology, and medical equipment due to their miniaturization, high frequency performance, reliability and durability, as well as broad compatibility. As wireless technology continues to evolve, the SMA plug connector will become even more important in high frequency applications.

〈Extended reading: SMA Connectors - The Most Common RF Connectors〉

What is SMA Plug Connector?

The SMA plug connector is very important in RF and microwave communications, ensuring the smooth transmission of signals between different devices. The structure and features of the SMA plug connector are as follows.

-

Threaded Connector Design:SMA plug connector is fixed by 1/4-36 inch internal threads to ensure a stable connection, avoid loosening, and provide good mechanical stability and vibration resistance.

-

Impedance Matching (50Ω):The standard impedance of SMA plug connector is 50 ohms (Ω), which reduces signal reflection and loss to ensure high performance transmission.

-

High Frequency Performance:The standard SMA plug connector supports DC up to 18 GHz, with pare of high performance versions available DC up to 26.5 GHz or higher for high frequency communications and test equipment.

-

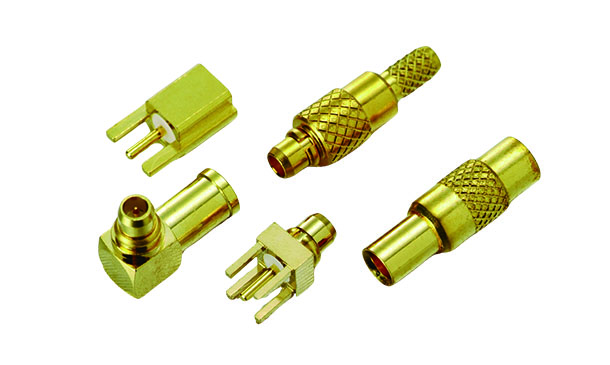

Material and Durability:Common materials used for SMA plug connector include gold-plated brass, stainless steel, etc., which can enhance durability and corrosion resistance.

〈Product Recommendations: SMA Plug Connector〉

〈Extended reading: SMA to K Connector Explained as the Key RF Component for High Frequency Technology〉

Types and Properties of SMA Plug Connector

There are two types of SMA plug connector. The SMA plug connector (SMA male) and the RP SMA plug connector (Reverse Polarity SMA Plug Connector). The main difference between these two types connector is about the polarity of center conductor. The center conductor is different. The standard SMA plug connector is not compatible with the reverse polarity SMA (RP SMA) connector. It cannot be directly connected to mate with female connector. The following is a description of the main differences between them:

〈Extended reading: 5 Minute Guide to Understanding the Uses and Applications of SMA Adapters〉

Product Specification

-

Standard SMA Plug Connector:Internal Male Pin.

-

RP SMA Plug Connector:Female Socket for internal mating.

As shown in the picture below, the top of the picture is RPSMA male & RPSMA female respectively, the bottom of the picture is standard SMA male & standard female respectively. We can see the difference is only in the gender of the center pin is exchanged, the other is the same.

Electrical Properties

In terms of electrical characteristics, the main difference between SMA plug connector and RP SMA plug connector is the polarity of the center conductor. Therefore there is basically no difference in electrical characteristics, both are equally stable and excellent.

How to Choose the Right SMA Plug Connector?

Frequency Range

Standard SMA Plug Connector:For DC-18 GHz

High Precision SMA plug connector (Precision SMA):DC up to 26.5 GHz or higher

Suggestion:If your application involves 5G, millimeter wave radar, or microwave communications, a high frequency SMA plug connector is required.

Polarity Selection:(Standard SMA V.S. RP SMA)

SMA (Standardized)

SMA Plug (Male):Internal thread with center pin

SMA Jack (Female):External thread with center hole

〈Extended reading: How Male SMA Connectors Drive Innovation in Global Tech?〉

〈Extended reading: High Performance Female SMA Connector: What You Need to Know!〉

RP SMA (Reverse Polarity SMA)

RP SMA Plug (Male):Internal thread with center hole (opposite of standard SMA)

RP SMA Jack (Female):External thread with center pin

Suggestion:Verify that your device is using RP SMA (e.g. Wi-Fi router, IoT device) to avoid not being able to connect.

Connection and Installation Requirements

-

Straight SMA Plug:Standard design for most RF devices.

-

Right Angle SMA Plug:Suitable for small space or special layout, reduce stress damage.

-

PCB Soldering Type (Edge Mount or Solder):Solder directly to the circuit board, suitable for RF module design.

-

Waterproof SMA Connector:Suitable for outdoor antennas, military and aerospace applications.

Suggestion:Select the SMA plug connector according to the needs of the end application.

Material and Durability

-

Brass with Gold Plating:Common, lower price. It is suitable for general applications.

-

Stainless Steel:Durable, corrosion resistant. It is suitable for military, aerospace, and laboratory testing environments.

Suggestion:Stainless steel or high quality SMA plug connector is recommended for high frequency applications or harsh environments.

Supplier and Quality Certification

-

Choose a supplier with ISO certification or military standards. (MIL-STD-348).

-

Ensure that the SMA connector meets RoHS (lead-free) or REACH (environmental) requirements.

Suggestion:Suppliers with international standard certificates are more secure.

Other Considerations (Special Applications)

Waterproof SMA (IP67 / IP68):Suitable for outdoor antennas, military equipment.

SMA Plug Connector Selection Table

|

Selection Factors |

Demand |

Recommandation |

|---|---|---|

|

Frequency Range |

< DC-18 GHz DC 18-26.5 GHz |

Standard SMA plug connector High Precision SMA plug connector |

|

Polarity |

Standard SMA RP SMA |

Most RF devices Wi-Fi, Wireless Module |

|

Shape |

Direct Right angle PCB Solder Type |

Standard Applications Use when space is limited RF Module |

|

Material |

Gold Plated Brass Stainless Steel |

General Applications |

|

Waterproof |

Outdoor Applications | IP67 / IP68 Waterproof SMA plug connector |

Installation and Maintenance of the SMA Plug Connector

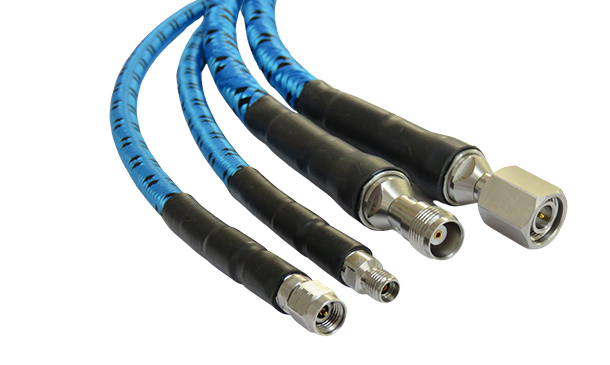

SMA plug connectors are widely used in wireless communication, RF test equipment and antenna systems. Proper installation and maintenance can ensure stable operation, minimize signal loss, and extend service life.

Part I: SMA Plug Installation Guide

Preparation before Installation

-

Check component:Verify that SMA plug matches jack type, including frequency range, polarity (standard SMA or RP SMA).

-

Clean the contact surfaces:Use a dust-free cloth or alcohol pad to clean the inner and outer surfaces of the connector to avoid dust or oil from affecting the signal transmission.

-

Preparation tools:Torque wrench (8 in-lbf inch-pound torque specification recommended) and dust free cloth.

The Correct SMA Connection Procedure

-

Step 1:Aligning the Connector

Ensure that the SMA plug (male) and SMA jack (female) are aligned in the same axis to avoid damage to the threads caused by forced insertion.

-

Step 2:Manual Rotation Fixing

Rotate the 1/4-36 inch threads by hand first to ensure a smooth lock-in and to avoid damage caused by misaligned threads.

-

Step 3:Tighten with a Torque Wrench (avoid over-tightening)

A Torque Wrench with a setting of 8 in-lbf is recommended. Over-tightening may damage the internal structure of the SMA plug connector, while over-loosening may affect signal quality.

-

Step 4:Confirm Connection Status

After the connection is complete, gently shake the SMA plug connector and it should be firm but not loose. If the connector is found to be abnormally noisy or unstable, disassemble it again and check if the threads are aligned.

Part II: SMA Connector Maintenance Recommendations

Regular cleaning and maintenance

-

Avoid Dust and Oil

Clean the inside of the SMA plug connector with a dust-free cloth or alcohol pad to prevent contamination from affecting the RF signal. Avoid touching the SMA center conductor directly with your hands to prevent sebum contamination.

-

Check for Oxidation and Plating Wear

The gold or nickel plating may wear off due to frequent plugging and unplugging, affecting conductivity. If the plating is found to be flaking off, consider replacing the SMA plug connector with a new one.

-

Avoid Moisture and Corrosion

Outdoor devices should use IP67 / IP68 waterproof SMA plug connector to prevent moisture ingress. In high humidity environments, a waterproof sealant (e.g. RTV silicone) is recommended.

〈Extended reading: Bulkhead SMA Connector Buying Guide: Specs, Materials & Applications〉

Torque Control and Prevention of Mechanical Stresses

-

Avoid Over-Tightening

Maximum torque should be 8 in-lbf (0.9 N-m). Over-tightening may cause the plating on the threads to peel off, resulting in poor electrical characteristics.

-

Avoid Pulling the Cable

The joint between the RF cable and the SMA plug connector is susceptible to stress. Make sure the cable is secured during installation to avoid unnecessary bending and pulling.

Avoid Static Damage

RF equipment should be ESD protected: Make sure the body or equipment is grounded before connecting the SMA plug connector. To prevent static electricity from damaging high frequency components. ESD bracelets or grounding cables can also be used.

Connector Troubleshooting

The possibilities and solutions of signal degradation or unstable connection for SMA plug connector.

SMA plug connector failure cause table

|

Issue |

Possible Causes |

Solutions |

|---|---|---|

|

Signal |

Poor internal contact, insertion and removal wear | Clean contacts and replace connectors as necessary. |

|

Bad |

Loose threads, oxidation | Retighten and check metal plating condition. |

|

Shorts |

Electrostatic discharge (ESD), moisture ingress | ESD protection added, waterproof SMA used |

Where to Buy a High Quality SMA Plug Connector?

Choosing the right SMA plug connector supplier is critical and will affect the performance, durability and long-term reliability of your product. Below are some key points to consider when selecting a quality connector supplier:

Product Quality and Technical Specifications

-

Frequency Range and Impedance Matching:Ensure that SMA plug connector meets the requirements of your application (e.g. DC-18GHz, DC-26.5GHz or even higher).

-

Materials and Durability:

-

Gold-Plated Brass:Good electrical conductivity. It is suitable for general applications.

-

Stainless Steel:Durable, corrosion-resistant. It is suitable for military, aerospace, and test equipment.

-

Teflon Dielectric (PTFE):Ensures low loss and stability.

Product life and grade

-

Life Cycle and Mechanical Strength:Standard SMA plug connector life cycle is at least 500 times.

-

Waterproof and Dustproof Rating (IP67 / IP68):Outdoor equipment (antennas, base stations) should be connected to a waterproof SMA plug connector to prevent signal degradation due to moisture ingress.

International Standards and Certifications

High quality suppliers of SMA plug connectors should comply with the following international standards to ensure product quality and reliability.

International Standards and Certification Table

|

Certification |

Use |

|---|---|

|

ISO 9001 |

Product Quality Management |

|

AS 9100 |

High reliability in aerospace, military, satellite, radar and other applications. |

|

RoHs(Lead Free) |

European Union Environmental Compliance |

|

REACH |

European Union Standards for the Management of Chemical Substances |

|

MIL-STD-348 |

Military Specification SMA Plug Connector Specification |

Technical Strength and Production Capacity of the Supplier

Ability to Design and Customize SMA Plug Connector

-

With a complete production line (R&D, manufacturing, testing), we are able to ensure quality control.

-

OEM or ODM customization service is available (custom frequency range, impedance, special structure design).

-

Test Equipment and Quality Control Procedures

S11, S21 Test (Vector Network Analyzer VNA):Detects insertion loss, reflection loss, and standing wave ratio (VSWR).

Salt Spray Test:Evaluates the corrosion resistance of connectors, especially for outdoor applications.

Able to Provide Test Reports

Quality suppliers should provide SMA plug connector S-parameter test report, VSWR test report, and durability test data.

Stability of Supply and Delivery Time

Supply Chain Management Capabilities-

The supplier shall have a stable source of raw material for SMA plug connector.

-

The supplier can ensure long-term supply to avoid production interruption due to shortage of parts.

Technical Support and After Sales Service

-

Able to provide technical consultation, product selection advice, installation guidance.

-

Can customer replace or return the product quickly when there is a quality issue?

〈Extended reading: Microwave Technology Principles and Applications〉

Huang Liang Technologies offers the SMA plug connector with the following advantages and features

-

Precision Manufacturing:SMA plug connector is low loss and high precision to ensure the best signal transmission.

-

High Environmental Resistance:IP67 waterproof and dustproof design. It is suitable for harsh environments.

-

Variety Selections:The SMA plug connector meets the needs of different RF and equipment applications.

-

Customization:With independent R&D capability and CNC equipment. The SMA plug connector can be customized to meet customers' special application requirements.

〈Extended reading: What Is High Frequency? High Frequency Features and Applications!〉

Conclusion

Huang Liang Technologies has its own R&D capability and CST electrical simulation software, which can satisfy the special application requirements of SMA plug connector. We also have a large number of CNC equipment, which can meet the high frequency precision tolerance requirements of SMA plug connector and provide fast delivery service. We have 110-GHz network analyzer and test equipment that can be used to test SMA plug connector and provide the best quality of products. If you have further inquiries, please feel free to contact us for more information!

〈Extended reading: What is mmWave? Advantages, Disadvantages and Applications!〉