- HOME

- Applications

- Blog

- SMA to K Connector Explained as the Key RF Component for High Frequency Technology

SMA to K Connector Explained as the Key RF Component for High Frequency Technology

25-03-12

In high frequency radio frequency (RF) technology applications, the choice of connector is critical. SMA to K connector is widely used, and SMA is required to connect the two in different frequency bands to K connector (SMA adapter or K (2.92mm) adapter). In this article, we will introduce the usage, design, specifications and the difference between SMA to K connector and standard SMA to SMA connector. We will also let you know how to select and maintain the SMA to K connector correctly.

〈Extended Reading: What are RF Connectors?〉

What is SMA to K Connector?

SMA to K connector plays a key role in RF equipment, helping to establish a connection between different types of connectors. SMA to K connector, also known as SMA adapter or K (2.92mm) adapter. It is a kind of connector that connects the interface between SMA type and K type. A brief introduction of SMA adapter and K (2.92mm) adapter is as follows.

- SMA adapter: It is a kind of widely used threaded connector in RF system, commonly used in lower frequency band.

- K (2.92mm) adapter: Designed for high frequency applications, it is a threaded connector with higher frequency range and lower loss.

〈Extended Reading: 5 Minute Guide to Understanding the Uses and Applications of SMA Adapters〉

Main Applications, Features and Benefits of SMA to K Connector

SMA to K connector is mainly used in RF systems that require high frequency transmission, low loss and high reliability. Below is a brief introduction of the main applications, features and advantages:

Main Uses:

- RF Test and Calibration: SMA to K connector is used for high frequency test equipment, such as network analyzers, spectrum analyzers, to ensure between the test equipment and the device under test accurate signal transmission.

- Microwave Communication and 5G Network: Used in high frequency communication equipment, such as 5G base station and satellite communication system, to ensure signal stability and low latency transmission.

- Radar and Aerospace Applications: The SMA to K connector is suitable for military and civil radar applications to ensure high frequency signal integrity, and for aerospace applications to meet high reliability requirements in extreme environments.

- High Frequency Electronic R & D & Laboratory Applications: For academic research institutions and corporate R & D departments of high frequency circuit testing and development.

〈Extended Reading: What is high frequency? High Frequency Features and Applications!〉

Features & Benefits:

SMA to K connector has significant advantages in high frequency applications. These features make the SMA to K connector becoming an important component in the RF field and ensure optimal performance in different applications. The following are its core features and benefits:

Key Features and Strengths of SMA to K connector

| Features | Strengths |

| High Frequency Support | Frequency range up to 40GHz and above. |

| Low Insertion Loss | Reduces energy loss during signal transmission and ensures signal strength. |

| High Reliability | High quality materials are used to ensure stable operation for a long time. |

| Good Impedance Matching | With 50 ohm design to minimize signal reflection and interference. |

| Resistant to High Temperatures and Environmental Disturbances | Ideal for extreme temperatures and harsh environments. |

Structural Analysis of SMA to K Connector

SMA to K Connector is a designed for high frequency applications in RF coaxial field. It is capable of transmitting signals in the microwave and millimeter wave frequency bands. The following is a brief description of the structure, connector types and common basic specifications for SMA to K Connector.

- Housing: Usually made of gold-plated brass or stainless steel to provide excellent electrical conductivity and corrosion resistance.

- Inner Conductor: Usually use high purity copper or gold plated to minimize insertion loss.

- Materials of Insulator: SMA to K connector uses PTFE (polytetrafluoroethylene) or other low dielectric coefficient materials to ensure good electrical performance.

〈Extended Reading: RF Coaxial Connector: A Key Component for Optimizing Microwave Communications〉

〈Extended Reading: What is Coaxial Cable and Characteristics〉

SMA to K Connector Type

SMA to K Connector types are all threaded and mechanically compatible, but SMA has a lower upper frequency limit (generally 18 ~ 26.5 GHz) and requires special attention, as it can cause performance problems with higher frequency bands (>18 GHz) if used. In addition to the common threaded design of SMA to K connector, there are several other types of connections.

Connection Method of SMA connector

- Standard SMA (Threaded): The most common type of SMA connector uses a 1/4"-36 threaded connection to ensure stability and low loss, and commonly used in wireless communications, test instruments, network analyzers as well as microwave testing.

- Quick Lock SMA (Quick Lock SMA): Screw less design, connected by a quick rotation mechanism. It is suitable for frequent plugging and unplugging applications, usually used in test equipment and laboratory environments.

- Reverse SMA (RP-SMA or Reverse Polarity SMA): The center contact of the inner conductor (male/female) is opposite to the standard SMA, usually used in Wi-Fi routers and antennas.

〈Extended Reading: SMA Connectors - The Most Common RF Connectors〉

Connection Method of K (2.92mm) connector

- Standard K Type (Threaded): The most common type of K connector is about 1/4"-36 threaded connection. It provides high frequency stability and commonly used in high frequency testing and millimeter wave communications.

- Quick Lock K Type: Screw less design and rotate to lock quickly. It is suitable for frequent plugging and unplugging scenes, usually used in high frequency test equipment.

〈Extended Reading: 2.92mm Connectors -The High Frequency Applications for Microwave Field〉

Common Basic Specifications

The basic specifications of SMA to K Connector include frequency range, impedance matching, loss consideration, mechanical durability and other related information. The following is a brief introduction to the common basic specifications:

Specifications of SMA to K connector

| Parameters | Specifications |

| Frequency Range | DC - 40GHz |

| Impedance | 50 ohm |

| Insertion Loss | Typically less than 0.3 dB |

| Return Loss | Better than 20dB |

| Mechanical Durability/Life Cycle | Can withstand at least 500 times of plugging and unplugging. |

| Materials | Gold-plated brass or stainless steel |

Difference between SMA to K Connector and SMA to SMA Connector

The SMA to K Connector and the SMA to SMA Connector have significant differences in design and application. The following is a comparison of the main differences between the two:

Products Comparison

| Products | SMA to K connector | SMA to SMA connector |

| Frequency Range | Up to 40 GHz | 18GHz for general applications and possibly up to 26.5GHz. |

| Main Application | Connects to SMA and K type devices to support high frequency applications. | Standard RF between connected SMA devices signal transmission. |

| Insertion Loss | Low loss design for high frequency testing | Relatively high, suitable for general RF applications. |

| Impedance | More precise 50ohm matching for reduced signal reflection. | Impedance matching of 50ohm. |

| Price | Higher (Due to high frequency support and precision design.) | Lower |

Selection, Maintenance and Installation of SMA to K Connector

SMA to K Connector Selection Guide

When selecting a suitable SMA to K Connector, the following factors should be taken into consideration:

- Frequency Range: Ensure that application requirements (e.g., 40 GHz) are met.

- Insertion Loss: Select a low loss design to maintain signal integrity.

- Impedance Matching: Ensure 50 ohm matching to minimize reflection loss.

- Material and Durability: Choose high quality gold plated or stainless steel material.

Installation and Maintenance Recommendations for SMA to K Connector

- Ensure that the connector is clean and that dust does not interfere with the signal.

- Use the correct tool to secure the threads to avoid over tightening and damaging the connector.

- Ensure that the connector is fully inserted to avoid poor contact.

- Avoid Frequent Plugging and Unplugging: Frequent plugging and unplugging may lead to a decrease in the precision of the connector.

- Regularly Check the Condition of Connectors: Check for signs of looseness or oxidation.

- Storage Environment: Avoid high humidity and extreme temperatures that may affect the life of the product.

Professional RF Microwave Connector Manufacturer – Huang Liang Technologies

Huang Liang Technologies provides all kinds of high quality and technical support, including:

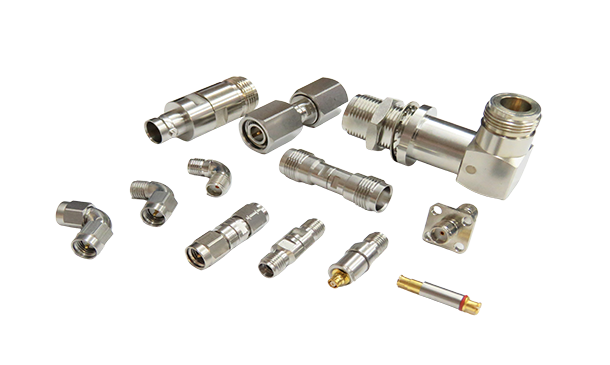

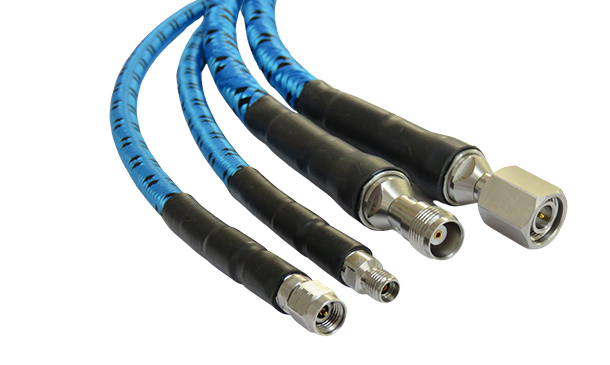

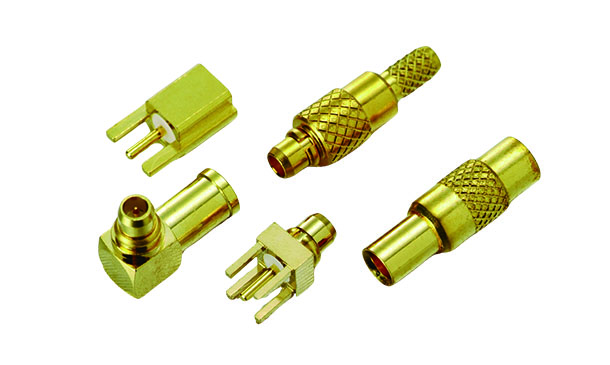

- RF microwave connector (SMA, K type, N type, 2.92mm, 2.4mm, etc.)

- RF connectors (SMA to K connector, N to SMA connector, K to 2.92mm connector, etc.)

- RF cables and components.

- Highly customized RF connector solutions.

〈Related Product: RF Connectors〉

〈Extended Reading: Microwave Technology Principles and Applications〉

Advantages of Huang Liang Technologies

- High Quality Manufacturing

- Precise design to ensure low loss and high reliability.

- Professional Technical Support

- Provide the technical services of select RF microwave cable assembly products and components.

- Wide Range of Products

- Satisfies a wide range of RF applications.

〈Extended Reading: RF Cables Major Characteristics, Applications and Key Points for Selection〉

Conclusion

SMA to K Connector plays a key role in high frequency RF applications. Its high frequency, low loss and excellent impedance matching characteristics makes it become an indispensable connection component for test equipment, microwave communications, radar and 5G technology. Choosing a high quality SMA to K connector can effectively improve system performance and ensure long term stable signal transmission. As a professional RF microwave connector manufacturer, Huang Liang Technologies offers a wide range of high quality products and technical support. If you have further requirements, please feel free to contact us for more information!