- HOME

- Applications

- Blog

- A Complete Guide to MMCX Connectors: Applications, Benefits, and How to Choose

A Complete Guide to MMCX Connectors: Applications, Benefits, and How to Choose

25-11-28

Introduction

Electronic products continue to evolve toward smaller, thinner, lighter, higher frequency, and higher speed designs nowadays. The demand for miniature RF connectors is growing rapidly particularly in wireless communications, IoT devices, wearables, and high-end audio products. The MMCX Connector (Micro-Miniature Coaxial) has become an indispensable RF interface in modern high-density electronic systems due to its compact size, stable bandwidth, and quick connection capabilities. As a miniaturized version of the MCX connector, the MMCX connector is suited for applications with limited space requiring highly reliable signal transmission. It is widely used in GPS modules, wireless modules, detachable headphone cables, and medical devices. This article will delve into the structural characteristics, application domains, and installation considerations of the MMCX connector, highlighting its crucial role in RF design.

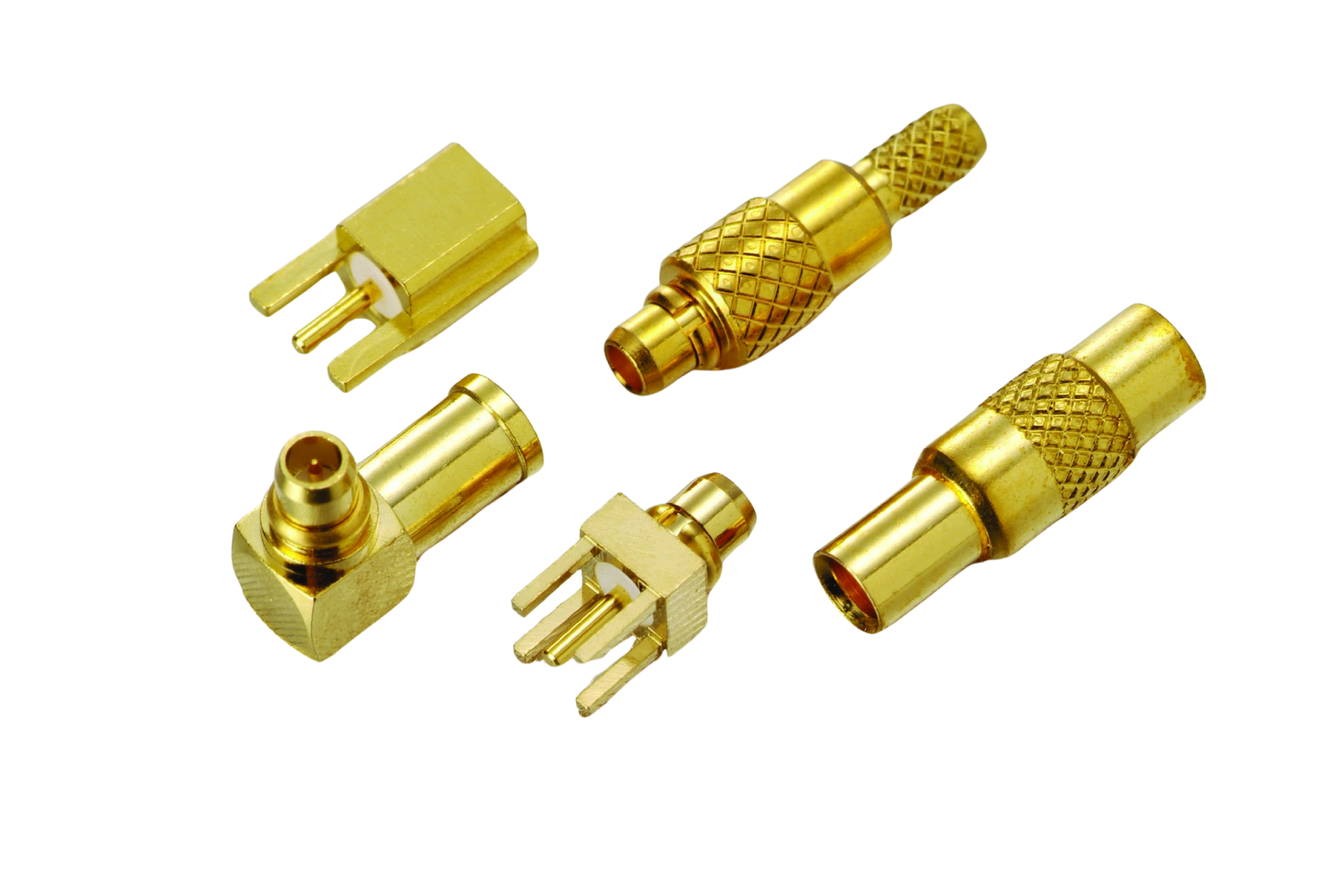

What is an MMCX Connector?

The MMCX connector is an extremely compact RF coaxial connector primarily used in wireless communication devices or electronic products where space savings are critical. It is a scaled-down version of the MCX connector, offering the same fundamental functionality but optimized for miniaturized equipment. Key features of the MMCX Connector include as below.

- Compact Size

- Snap-on Coupling

- Rotation Capability

- Frequency Range

- Excellent Electrical Performance

Below are the advantages of MMCX Connectors

|

Advantages |

Description |

|---|---|

|

Compact Size |

Ideal for space-constrained devices |

|

Quick Connect |

Snap-on design requires no tools |

|

High Frequency Performance |

Supports GHz-level RF transmission |

|

Excellent Durability |

Designed for hundreds of mating cycles |

Applications of MMCX Connectors

Due to its compact size, stable performance, and rotatable connection, the MMCX connector is widely used in various devices requiring high frequency signal transmission with limited space. Below are its primary application fields.

- Wireless Communication Devices

Examples of wireless communication devices utilizing MMCX connectors, e.g. Wi-Fi modules, Bluetooth modules, LTE/5G antenna modules, wireless base stations, transceivers.

Advantages: Used to connect antennas to modules, ensuring stable high frequency signal transmission.

- Detachable Earphone Cables

MMCX connectors are widely used in high-end in-ear monitors (IEMs), allowing users to replace earphone cables for enhanced maintainability and expandability (e.g., switching to Bluetooth cables or upgrading cable materials). The connector's 360-degree rotation capability prevents cable damage from pulling and improves wearing comfort.

Advantages: Great durability, plug-and-play design, stable signal transmission, compact size.

- IoT Devices

The MMCX connector is a common antenna connection method in many smart sensors, trackers, and industrial IoT modules. It is suitable for PCB designs in confined spaces, particularly in modular devices (such as NB-IoT, LoRa, and Zigbee modules).

Advantages: Compact size, high design flexibility, easy integration with motherboards, rotatable for convenient layout.

- GPS/GNSS Devices

Applications of MMCX Connector: GPS positioning modules, automotive navigation systems, dashcam-navigation integrated systems.

Advantages: MMCX connectors are commonly used for GPS antenna connections due to their compact size and ease of installation in space-constrained devices.

- Mobile Devices and Wearable Products

Applications of MMCX Connector: Internal antenna modules in smartphones, smartwatches, fitness trackers, medical wearables (e.g., heart rate monitors).

Advantages: Compact design and rotatable connection make it suitable for devices with frequent bending or movement.

- Laptops and Wireless Expansion Modules

Applications of MMCX Connector: Wi-Fi cards in laptops, wireless USB dongles, and modular development boards (e.g., Raspberry Pi, Arduino expansion boards).

Advantages: Internally connects antennas to modules, saving space while ensuring signal quality.

- Medical Devices

Applications of MMCX Connector: Portable diagnostic instruments, wireless physiological monitors (e.g., ECG, EEG), medical sensor modules.

Advantages: Compact size and high stability make it suitable for precision medical environments.

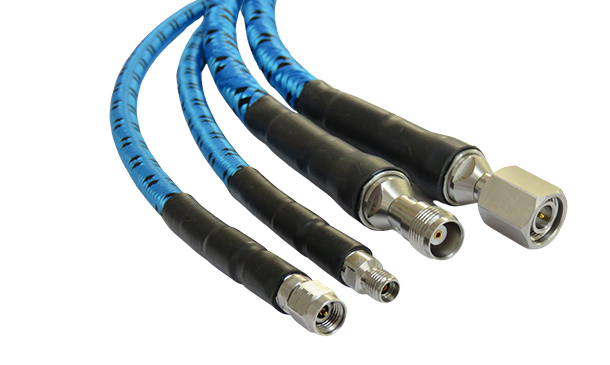

- Test and Measurement Equipment

Applications of MMCX Connector: RF test fixtures, module connectors in communication test instruments.

Advantages: In testing environments, MMCX provides a convenient, fast, and stable connector solution.

- Military and Aerospace Applications

Applications of MMCX Connector: Military wearable devices, compact flight communication modules (e.g., drones).

Advantages: High reliability and shock resistance, suitable for harsh environments.

Polarity for MMCX Connectors

When using MMCX connectors for radio frequency (RF) signal connections, correctly distinguishing positive and negative terminals (polarity) is critical to ensure signal integrity and safe device operation. Details as follow.

- Structural Description

The MMCX connector is a coaxial connector featuring a concentric design comprising two primary components: the central pin and the outer shell ground.

|

Part |

Function |

Polarity |

|---|---|---|

|

Inner Pin |

Transmits primary RF signals (signal core) | Positive terminal (Signal/Hot) |

|

Outer Shell |

Provides shielding and grounding | Negative terminal (Ground/Shield) |

- How to Identify and Install

|

Item |

Description |

|---|---|

|

Center Pin Identification |

The plug end features a protruding metal pin (male connector), while the jack end has a corresponding receptacle (female connector), and this constitutes the positive signal transmission path. |

|

Outer Shell Identification |

The outer casings of plug and jack form a tight electrical grounding path. This connection must be secured to the ground wire (GND) or ground plane. |

|

Notes |

The center pin must not be misconnected or shorted to ground, as this will cause signal distortion, interference, or damage to the module |

- Consequences of Reverse Polarity Connection

|

Issue |

Result |

|---|---|

| Center Pin Misconnected or Misaligned | RF signal transmission failure or severe distortion. |

| Enclosure not Properly Grounded | Failure to shield noise, potentially causing EMI or signal interference. |

| Center Pin Shorted to Ground | Damage to transmitter module, driver circuitry, or even overheating/burnout. |

| Excessive Force or Incorrect Direction During Insertion/Removal | May break the center pin, rendering it unusable. |

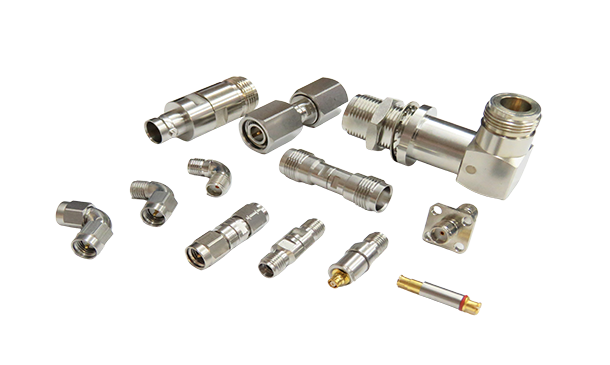

Comparison of MMCX Connectors with Other Connectors

Below is a comparison table of the MMCX connector versus three other common RF connectors such as SMA, MCX, and BNC. The table compares dimensions, frequency range, connection methods, and common applications.

|

Characteristic |

MMCX Connector | SMA Connector | MCX Connector | BNC Connector |

|---|---|---|---|---|

| Dimensions | Very small (approx. 3.5 mm diameter) | Compact (approx. 8 mm diameter) | Small (approx. 4.5 mm diameter) | Medium (Approx. 14.5 mm diameter) |

| Frequency Range | DC ~ 6 GHz | DC ~ 18 GHz (High quality up to 26.5 GHz) |

DC ~ 6 GHz | DC ~ 4 GHz (typically 0~2 GHz) |

| Connection Method | Snap-on | Screw-on | Snap-on | Bayonet |

| Mechanical Cycle | Approximately 500 insertions/removals | Approximately 500 insertions/removals | Approximately 500 insertions/removals | Approximately 500 insertions/removals |

| Impedance | 50 ohms | 50 ohms | 50 ohms or 75 ohms | 50 ohms or 75 ohms |

| Waterproof Performance | No special waterproof design | Waterproof models available depending on model | No special waterproof design | Generally no waterproof design |

| Primary Applications | Mobile devices, GPS modules, antenna modules | Test equipment, communication equipment, microwave modules | Mobile devices, wireless communication modules | Video equipment, laboratory test equipment |

| Installation Stability | General | High (screw-mounted) | Average | Moderate (bayonet mount) |

| Space Considerations | Ideal for space-constrained equipment | Suitable for relatively spacious environments | Suitable for medium space requirements | Not suitable for space-constrained equipment |

| Cost | Moderate to low | Medium to high | Moderate | Low to moderate |

How to Select the Right MMCX Connector?

When selecting an MMCX connector, evaluate based on the following criteria to ensure it meets your product's electrical, mechanical, and environmental requirements.

- Mechanical Structure and Size Considerations

- Electrical Performance Parameters

- Application Scenarios and Connection Methods

- Environmental and Durability

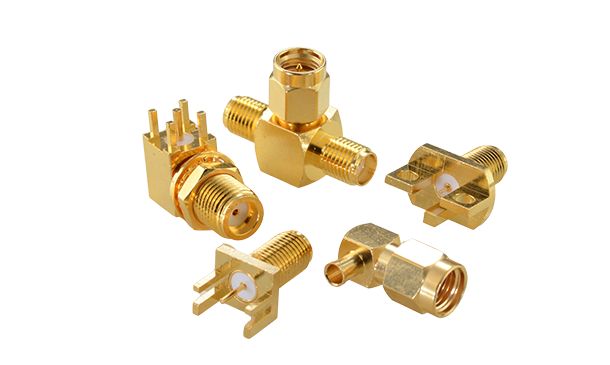

Top MMCX Connector Supplier Recommendation: Huang Liang Technologies

When selecting a high-end MMCX connector supplier, considerations extend beyond product performance to include the supplier's R&D capabilities, quality systems, and delivery reliability. We offer the following advantages across four key areas like technical, quality, production capacity/delivery, and technical support.- Technical Capabilities

|

Requirements |

Description |

|---|---|

| High-Frequency Characteristic Control Capability | Capable of designing and manufacturing MMCX connectors supporting up to 6 GHz with VSWR < 1.25. |

| Complete Product Lineup | MMCX connectors offer a complete range of models including straight, right-angle, male/female, board-to-wire, and wire-to-wire. |

| Simulation and Matching Capabilities | Possesses RF simulation capabilities (e.g., HFSS, CST) to achieve optimal impedance matching. |

| Durability and structural reliability testing | MMCX connector provides a mating cycle life test report (over 500 cycles) and has passed torque, vibration, and shock testing. |

| Customization Capabilities | Can be customized to meet specific application requirements (e.g., specific gold plating thickness, modified latching force, high-temperature resistance specifications) |

- Quality and Certification System

|

Conditions |

Description |

|---|---|

| ISO 9001 Certification | Basic Quality Assurance System |

| RoHS / REACH Compliance | Guaranteed free of hazardous substances, compliant with EU environmental regulations. |

| Reliability Test Reports | Including salt spray testing, thermal aging resistance, thermal cycling, etc. |

| Traceability | Records for raw materials/batches/inspections are available for inquiry. |

- Production Capacity and Delivery Capability

|

Conditions |

Description |

|---|---|

| Stable Supply Capability | Consistent monthly production volume capable of handling large-scale OEM/ODM projects. |

| Rapid Lead Times | Standard products delivered within 2–4 weeks. Expedited processing available for urgent orders. |

- Engineering Support

|

Requirments |

Description |

|---|---|

| Provide 3D CAD / electrical models | Quickly provide STEP, DXF, S-parameter, and other models. |

| RF design consulting capabilities | Professional FAE support for antenna and PCB trace design matching. |

| Rapid sample support | Rapid sample delivery and model recommendations during project initiation. |