- HOME

- Applications

- Blog

- Coax Cable Assemblies in Modern Communication Systems

Coax Cable Assemblies in Modern Communication Systems

25-12-25.jpg)

Introduction

In modern high-frequency electronic applications, coaxial cable assemblies play a critical role in ensuring signal integrity and stable system operation. Whether maintaining audio-visual quality in broadcast transmission, ensuring secure and reliable data exchange in military communications, transmitting high-resolution signals in medical imaging equipment, or supporting high-bandwidth and low-latency requirements in RF communications and high-speed data transmission systems. These applications all rely on precision coax cable assemblies to achieve optimal performance.

Coax cable assemblies not only impact overall system signal stability, insertion loss, phase consistency, and electromagnetic shielding effectiveness, but also serve as the critical bridge between connectors and system modules. As technologies like 5G, satellite communications (SATCOM), radar sensing, and high frequency test instruments continue to advance. The specifications demanded of coax cable assemblies grow increasingly stringent. This article will delve into the structural design, material selection, performance variations, and application domains of coax cable assemblies, helping readers gain a comprehensive understanding of how to select and design high-performance RF coax cable assemblies that best meet their requirements.

What are Coax Cable Assemblies?

Coaxial cable assemblies are complete transmission line components consisting of coaxial cables paired with RF connectors, used to transmit electromagnetic wave signals in high-frequency systems. Their key feature is the coaxial arrangement of inner and outer conductors, which effectively reduces electromagnetic interference (EMI) and maintains impedance consistency. This ensures stable, low-loss signal transmission over long distances and at high frequencies. Coax cable assemblies are widely used in communication systems, military radar, test instruments, medical imaging, satellite and navigation equipment, and other fields with extremely high signal quality requirements.

- Center Conductor: The primary channel for transmitting radio-frequency current. Common materials include copper, silver-plated copper, or tinned copper. Surface treatment and dimensional accuracy of the conductor affect insertion loss and phase stability during high frequency transmission.

- Dielectric Insulator: Envelops the center conductor to maintain conductor spacing and control characteristic impedance. Common materials include PTFE (Polytetrafluoroethylene) or PE (Polyethylene). The dielectric constant and loss tangent of the material significantly affect signal velocity and the stability.

- Outer Conductor / Shield: Provides electromagnetic shielding and serves as a current return path. Can be braided mesh (Braid Shield), foil layer (Foil Shield), or semi-rigid metal tube (Semi-Rigid Tube). Higher shielding quality enhances resistance to interference (EMI/RFI).

- Outer Jacket: Protects internal components from moisture, abrasion, and chemical corrosion. Common materials include FEP, PVC, or silicone. Environmentally resistant materials are selected for specialized applications (e.g., high temperatures, salt fog, aerospace).

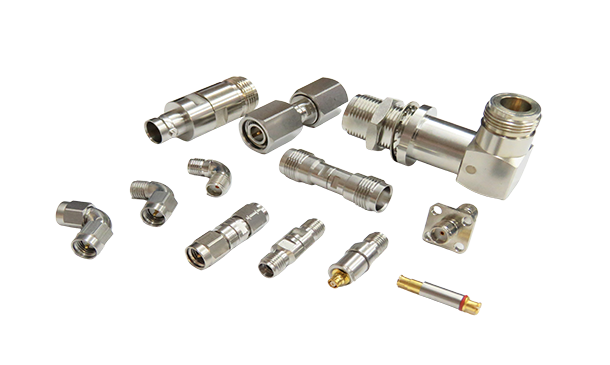

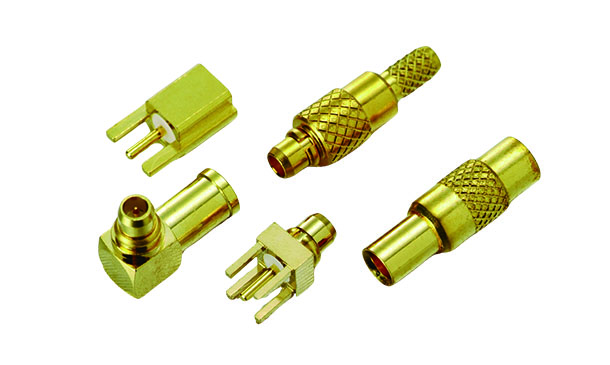

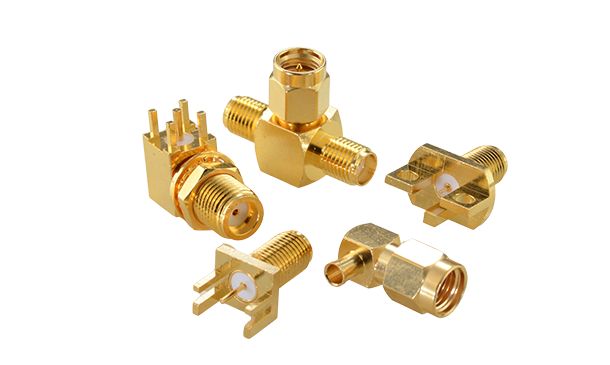

- RF Connector: Installed at both ends of the coaxial cable to connect system ports or modules. Types include SMA, K (2.92 mm), N, TNC, MCX, MMCX, etc. High quality connectors ensure impedance matching and low reflection (low VSWR), enhancing overall assembly reliability.

Advantages of Coaxial Cable Assemblies

Coaxial cable assemblies are the most common and reliable signal transmission medium in RF and high frequency communication systems. Their structural design combines electrical stability with mechanical strength, meeting demanding requirements from laboratory testing to military systems.- Easy Installation, High Integration: Coax cable assemblies feature a modular design with standardized RF connectors (e.g., SMA, N, K, MCX) at both ends. They enable rapid installation or replacement, minimizing system downtime. Ideal for frequent plug-and-play use in laboratory testing environments or production lines.

- Superior EMI/RFI Shielding: Utilizing dual or triple-layer shielding (braided and foil layers) effectively suppresses external electromagnetic interference. Maintains low crosstalk and high signal integrity in high density systems. Particularly suitable for military, aerospace, and satellite communications where signal reliability is paramount.

- High Structural Stability and Durability: The outer jacket features abrasion resistance, temperature tolerance, and moisture resistance, making it suitable for outdoor or harsh environments. Precision connectors and tight soldering ensure long-term mechanical stability and low contact resistance. Certain high-end models incorporate vibration and shock resistance designs for aerospace and automotive electronics applications.

- Supports High Frequency and Broadband Signal Transmission: Capable of handling frequencies from DC to tens of GHz (depending on cable and connector). Maintains stable characteristic impedance while minimizing VSWR and reflection loss. Suitable for 5G, millimeter-wave (mmWave), radar sensing, and high speed data transmission applications.

- High Customization Flexibility: Can be designed with varying lengths, connector types, or cable structures per requirements. Project-specific designs are available for diverse applications.

Applications of Coax Cable Assemblies

Coax cable assemblies leverage their superior high frequency transmission capabilities, interference resistance, and structural stability to serve as critical components, ensuring stable signal transmission across various RF and high frequency systems. They play a pivotal role in data communication, medical equipment, and defense applications, acting as the key application scenarios as follows.- Telecommunication & Networking

- Broadcast & AV Systems

- Broadband & Data Communication

- Medical Equipment

- Defense & Aerospace Applications

- Industrial Automation and Test Equipment

Primary Types of Coax Cable Assemblies

Coax Cable Assemblies can be categorized into multiple types based on structural rigidity, flexibility, and application environments. Each type exhibits distinct differences in signal transmission performance, mechanical durability, and installation methods. Below is an introduction to the primary types of coax cable assemblies:- Hardline Coaxial Cables

- Structural Characteristics: Utilizes a metal tube (e.g., copper or aluminum) as the outer conductor, with the inner conductor typically being a hollow or solid copper core. Features extremely low insertion loss and high power handling capability.

- Electrical Performance: Stable impedance and low loss, suitable for long-distance or high-power RF transmission.

- Applications: Main trunk lines for broadcast transmission towers and base stations, satellite earth stations, high-power radar and communication systems, large test platforms, and microwave transmission terminals.

- Semi-Rigid Coaxial Cables

- Structural Characteristics: Features a metal tube (typically copper or aluminum) as the rigid outer conductor, filled internally with PTFE insulation. Delivers optimal electrical performance and minimal VSWR, but cannot be bent.

- Electrical Performance: Frequency range extends beyond 40 GHz, featuring extremely low insertion loss and high phase stability.

- Applications: Precision RF modules, internal connections in microwave circuit boards, military and aerospace high-frequency systems, test instruments (e.g., VNAs, power meters, microwave receiver modules)

- Formable Coaxial Cables (Conformable)

- Structural Characteristics: Similar to Semi-Rigid structure, but with a flexible outer conductor made of bendable metal tubing (e.g., aluminum-tin alloy). Can be manually or tool-formed to maintain a predetermined bend angle.

- Electrical Performance: Slightly lower performance than Semi-Rigid, but offers installation flexibility and good phase stability.

- Applications: Internal interconnects in microwave modules (replacing semi-rigid wires), devices with space constraints or fixed routing requirements, radar modules, communication front-ends, and RF filter modules.

- Flexible Coaxial Cables

- Structural Characteristics: Features a braided mesh shield and flexible jacket, allowing free bending and easy installation. Further subdivided into standard, low-loss, and high-flex types based on structure.

- Electrical Performance: Frequency range covers DC to 26.5 GHz (depending on wire gauge and material), though insertion loss is slightly higher than semi-rigid types.

- Applications: Laboratory test leads/VNA cables, wireless communication equipment and base station connections, medical imaging, industrial sensing, temporary test assemblies, and applications requiring frequent plugging/unplugging and active connections.

Coax Cable Assembly Testing Process

- Coax Cable Assemblies Electrical Performance TestingThe electrical testing process primarily includes the following checks, as described below.

- Continuity Test: Use an automatic tester to verify electrical continuity between the center conductor and outer conductor. Detect open circuit (Open) or short circuit (Short) anomalies.

- Impedance Test: Use a Time Domain Reflectometer (TDR) to measure the total line impedance.

- Insertion Loss (IL): Measured using a Vector Network Analyzer (VNA) within a specified frequency range.

- Return Loss / VSWR: Tests impedance matching and reflection effects.

- Insulation Resistance: Resistance between the center conductor and the outer conductor.

- Dielectric Withstanding Voltage: Withstands specified conditions without breakdown or discharge.

- Mechanical and Environmental Testing for Coaxial Cable Assemblies

- Pull Test: Assesses connector retention strength using a tensile testing machine.

- Flexing/Bend Test: Continuous testing under 90° bending conditions. Ensures stable electrical continuity and minimal insertion loss variation.

- Vibration Test: Conducted per MIL-STD-202 or IEC 60068 standards. Simulates long-term vibration loads in transportation or aerospace applications.

- Salt Spray Test: Simulates marine environment corrosion conditions. After 48 to 96 hours, no significant oxidation or plating peeling shall appear on the connector surface.

- Thermal Cycle Test: Repeated cycling within the temperature range of −40°C to +85°C. Verifies material thermal expansion matching and structural stability.

How to Select the Right Coax Cable Assemblies?

When selecting suitable coax cable assemblies, beyond basic pricing considerations, evaluation should encompass multiple critical aspects to ensure product quality and functional benefits. Below are key recommendations for choosing appropriate coax cable assemblies.- Impedance Matching

- Required Frequency Range and Loss Specifications

- Connector Type & Mechanical Requirements

- Operating Environment and Material Selection

- Supplier Capability & Reputation

Products Features and Advantages of Huang Liang Technologies

- Technical Integration Capabilities & Customization: Extensive design expertise in impedance matching, phase stability, and low insertion loss. Capable of customizing cable structures, phase matching, and other technical processes per client requirements.

- Comprehensive Testing Facilities and Rigorous Quality Assurance: In-house VNA, TDR, tensile testing machines, and environmental test equipment. Pre-shipment test reports including IL/RL/Phase/TDR are provided, backed by ISO-standardized quality control.

- Diverse Materials and High-Reliability Components: Coax cable assemblies offer flexible, formable, semi-rigid, and hardline cable types. Sheath materials include FEP, PUR, and Silicone. Connectors feature high frequency grades like SMA, N, K, and 3.5mm. Special coatings and corrosion protection are available.

- Rapid Prototyping and Flexible Production Capacity: Supports rapid sample development, seamless transition between small-batch/diverse production and high-volume manufacturing, with highly flexible lead time management and material procurement. Ideal for both R&D and mass production phases.

- Extensive Application Domain Experience: Proven track record in telecommunications (5G, base stations), satellite communications, radar, medical instruments, and test equipment. Deep understanding of specification priorities and compliance requirements across diverse fields.

- Technical Support and After-Sales Service: Provides consultation on coax cable assembly selection, test data analysis, and on-site support. For phase matching or system-level integration needs, assists in defining test specifications and acceptance criteria.

Conclusion

As RF and microwave technologies continue to evolve, demands for the performance and stability of coax cable assemblies grow increasingly stringent. Every stage from design and material selection to assembly impacts signal quality and system reliability. Therefore, selecting a partner with proven expertise is fundamental to ensuring product performance.As a leading manufacturer of coax cable assemblies in Taiwan, Huang Liang Technologies offers a comprehensive product line and years of practical experience. We provide high-quality coaxial connectors, adapters, coaxial cables, and customized assemblies widely used in communications, aerospace, defense, and other fields. We also provide technical consultation and product selection guidance to help customers develop optimal solutions. For inquiries regarding product specifications, application requirements, or technical support, please contact us just now. We will assist you with professional service to fulfill your needs.