- HOME

- Applications

- Blog

- Bulkhead SMA Connector Buying Guide: Specs, Materials & Applications

Bulkhead SMA Connector Buying Guide: Specs, Materials & Applications

25-05-29.jpg)

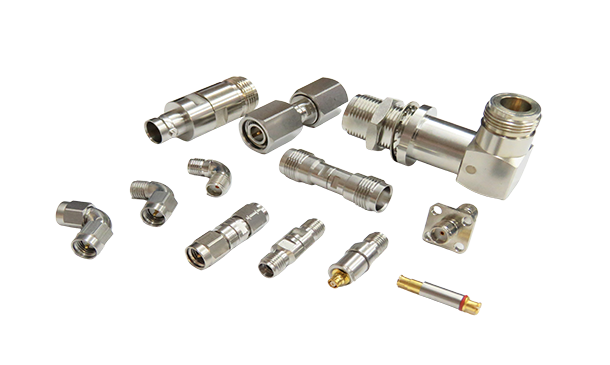

The bulkhead SMA connector is a key component in RF equipment chassis to realize stable internal and external signal transmission. Its structure is designed to pass through the equipment panel and maintain good RF connection quality, which is widely used in communication, measurement, national defense and other fields. In this article, we will comprehensively introduce the bulkhead SMA connector's technical specifications, material selection, installation and maintenance methods, and how to select a reliable supplier to help you make the right judgment when purchasing.

〈Extended reading: SMA Connectors - The Most Common RF Connectors〉

What is Bulkhead SMA Connector?

The bulkhead SMA connector is a bulkhead mountable SMA series RF connector featuring extended threads and retaining nuts for secure mounting on equipment enclosures or panels. The bulkhead SMA connector is designed with enhanced structural mounting compared to a typical SMA connector, and is especially suited for use in situations where external antennas or signal lines need to be connected from inside the equipment.

-

The bulkhead SMA connector with nut and extension threads for securing to bulkhead holes.

-

The Bulkhead SMA connector is installed for better shielding and grounding.

-

Suitable for the connection of RF module which is separated from inside and outside of the chassis.

-

Maintains the high frequency characteristics and standard impedance of the SMA series.

〈Extended reading: The Ultimate Guide to SMA Plug Connector Types and Specifications〉

What are the Specifications for the Bulkhead SMA Connector?

When selecting a suitable bulkhead SMA connector, the crucial specifications need to be evaluated. The following table lists common technical parameters and application-specific descriptions to assist you in making a selection based on your actual needs.

〈Extended reading: How Male SMA Connectors Drive Innovation in Global Tech?〉

〈Extended reading: High Performance Female SMA Connector: What You Need to Know!〉

SMA Connector Specification Table

|

Specification |

Standard Value |

Description & Application |

|---|---|---|

|

Frequency Range |

DC ~ 26.5 GHz |

High frequency applications (e.g. radar, 5G, measurement instruments) |

|

Impedance |

50 ohm |

Compatible with most RF equipment to ensure signal reflection is minimized. |

|

VSWR |

≦1.20 | Low VSWR with low reflection and high transmission efficiency |

|

Voltage |

500 to 1000V | Especially for high voltage testing or signal protection scenarios. |

|

Thread |

1/4"-36 UNS-2A | Match the nut, install to make sure the diameter of the hole and the threads are complete. |

|

Bulkhead |

Ø6.4~7.2 mm | Hole size to be designed to fit the bulkhead SMA connector configurations. |

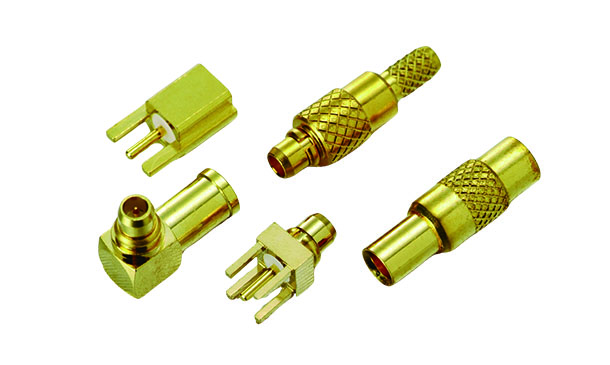

Material Selection for Bulkhead SMA Connector

The conductor and housing materials of bulkhead SMA connector have a decisive impact on RF performance, durability and cost. The following is a comparison of common materials used in the bulkhead SMA connectors.

〈Product Recommendations: Bulkhead SMA Connector〉

Material Comparison Table of SMA Connectors

|

Material |

Advantages |

Disadvantages |

Applicable Areas |

|---|---|---|---|

|

Stainless Steel |

High strength, anti-corrosion, long life | Higher cost and more difficult to process | Military specification equipment, outdoor systems, high reliability equipment |

|

Brass |

Cost-effective and good electrical conductivity | Weak resistance to long-term oxidation | Commercial RF Modules, Communication Products |

|

Brass |

Excellent electrical conductivity and strong oxidation resistance. | Higher cost, need to protect the coating | High frequency test, microwave instrumentation, aerospace or precision measurement modules |

|

Aluminum |

Low weight, low cost | Mechanical strength and corrosion resistance are slightly weaker. | Portable devices, weight limiting module applications |

How to Install and Maintain Bulkhead SMA Connector?

Proper installation and maintenance of the bulkhead SMA connector is critical to ensure the long-term stability of your system. Improper installation and maintenance can lead to signal loss, unstable connection and even equipment damage. To ensure the long-term stability of the bulkhead SMA connector in RF applications, it is recommended the following installation and maintenance recommendations. Be followed in conjunction with the proper tools and periodic inspection regimes.

〈Extended reading: 5 Minute Guide to Understanding the Uses and Applications of SMA Adapters〉

The Size of Hole should be Accurate

The panel aperture recommended of the SMA bulkhead connector is about Ø6.4 ~ 7.2mm. When the panel aperture is too large will cause the connector to wobble. On the other hand, if the panel aperture is too small will affect the assembly, it is necessary to consider whether the threaded portion of the panel can be completely penetrated, to avoid interference affecting the fixation of the nut.

The Force Applied should be Moderate and Even

It is recommended to use a torque wrench to apply the force (approx. 0.45 to 0.9 N-m) to avoid damage to the bulkhead SMA connector.

Regularly Check the RF Performance

VSWR, Return Loss, etc. can be measured using a VNA. If you notice an increase in VSWR or abnormal return loss of the bulkhead SMA connector, it may be a sign of a loose or damaged connector.

Keep Clean and Avoid Pollution

The interface between the center pin of bulkhead SMA connector and the housing should be free from oil, dust, and moisture, which may affect the signal quality.

Notes on Storage and Transportation

Store in an anti-static bag to avoid oxidization or static damage to the connector, and use impact foam to secure the bulkhead SMA connector during transportation to avoid pressure or bending of the pins.

How to Choose a Quality Supplier for Bulkhead SMA Connector?

Choosing a reliable supplier is crucial to the long-term stability of bulkhead SMA connector supply and technical support. Below is a compilation of common evaluation criteria, and the advantages of our expertise.

Evaluation Table of SMA Connector Suppliers

|

Evaluation |

Suggested Checkup Items |

Advantages of Huang Liang Technologies |

|---|---|---|

|

Quality Assurance |

Quality standards such as ISO 9001, RoHS, etc. | All products are ISO and RoHS certified. |

|

RF Test Capability |

Can you provide complete test reports on VSWR, insertion loss, reflection, etc.? | In-house laboratory with full support for high-frequency testing. |

|

Customized |

Customized sizes, materials, special structures, etc. are available. | Provide project design and fast sample delivery. |

|

Minimum |

Flexibility, whether to support samples or small amount of trial production. | MOQ Flexibility for R&D and small volume production. |

|

Service |

Availability of specialized personnel to assist in design and technical consultation. | Engineering team provides product diagrams, application suggestions, and 3D drawings. |

Conclusion

The bulkhead SMA connector is a key component to realize stable transmission of high frequency signals, and its design and quality will directly affect the performance and life of the equipment. From frequency specification, material structure to installation and maintenance, every aspect is worth paying attention to choosing the right bulkhead SMA connector. It will ensure your system's long-term stability and operation. As a professional RF microwave connector manufacturer, Huang Liang Technologies offers a wide range of high quality products and technical support. We provide complete services from standard products to customized development. As well as we have perfect RF test equipment and professional technical team. Please contact us for more information, and let us be your best support for RF connectivity solutions!

〈Extended reading: What is 5G Millimeter Wave? Key Differences and Features Over Regular 5G〉