- HOME

- Applications

- Blog

- What are 1.85mm Connectors Key Components for High Frequency Applications

What are 1.85mm Connectors Key Components for High Frequency Applications

25-09-02

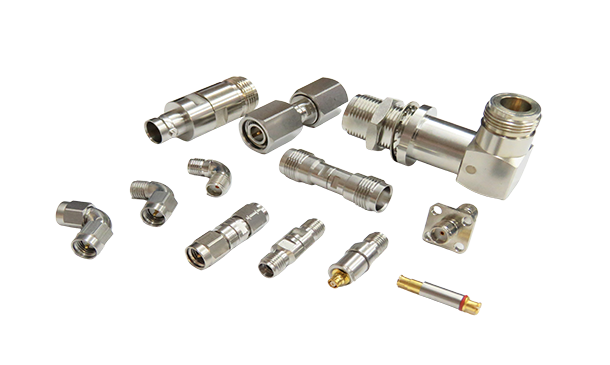

In rapidly advancing RF and millimeter-wave technology landscape, demand for high-precision, high-frequency components continues to surge. Among these, 1.85mm connectors have become indispensable key components due to their ability to reliably transmit signals at frequencies up to 65 GHz and beyond. With their precision design and exceptional performance, 1.85mm connectors are widely utilized in cutting-edge fields such as aerospace, telecommunications, as well as advanced test and measurement systems.

This article will delve into what 1.85mm connectors are, why they are important, and their practical roles in various high-frequency applications. Whether you are an engineer, technician, or reader interested in the technology behind high-frequency communication systems, understanding these connectors will help you grasp the development trends in RF and microwave technology.

〈Extended reading:What Is High Frequency? High Frequency Features and Applications!〉

What are 1.85mm Connectors?

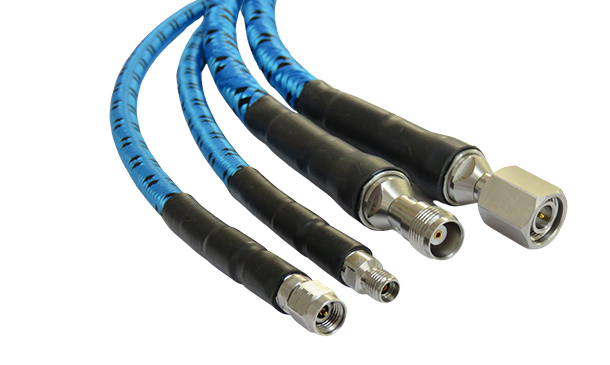

1.85mm connectors are high-frequency radio frequency (RF) coaxial connectors specifically designed for stable operation at frequencies up to 65 GHz and beyond. The name derives from its 1.85mm inner diameter gap between central conductors. As a type of millimeter-wave connector, it is commonly found in high-frequency communication and test equipment such as vector network analyzers (VNAs), millimeter-wave modules, radar systems, and advanced communication systems.

Unlike common SMA or N connectors, 1.85mm connectors feature tighter manufacturing tolerances and smaller structural dimensions. They utilize an air dielectric and high-quality metallic materials (such as stainless steel or gold-plated contacts) to ensure low VSWR and excellent signal integrity even at extremely high frequencies. Additionally, 1.85mm connectors are mechanically compatible with 2.4mm connectors but incompatible with SMA or 2.92mm (K) connectors, preventing damage or signal degradation caused by mismatched dimensions and structures.

〈Product recommendation:1.85mm ST. JACK CONNECTOR PCB END LAUNCH CONNECTOR TO ∅.005 PIN〉

Technical Features of 1.85mm Connectors

1.85mm connectors are designed for high-frequency applications, enabling signal transmission within microwave and millimeter-wave bands. Key features of 1.85mm connectors include as below.

Support for Ultra-High Frequencies (up to 65 GHz)

1.85mm connectors support frequencies up to 65 GHz, with some high-end designs capable of even higher frequencies. This makes them ideal for millimeter-wave and ultra-wideband applications.

Low VSWR (Voltage Standing Wave Ratio)

Through precision structural design and air-dielectric transmission lines, 1.85mm connectors maintain low VSWR, minimizing signal reflection and loss. This ensures high-quality signal transmission and measurement accuracy.

Compatibility with 2.4mm Connectors

Despite slight dimensional differences, 1.85mm connectors are mechanically compatible with 2.4mm connectors, allowing interconnection without performance degradation and enhancing application flexibility. However, note that 1.85mm connectors are incompatible with SMA or 2.92mm (K) connectors.

〈Product recommendation:2.4mm Connectors〉

High Reliability and Durability

1.85mm connectors are typically manufactured from stainless steel or other materials of equivalent high strength, capable of withstanding repeated insertion/removal cycles and harsh environmental conditions, making them suitable for both laboratory and field applications.

Precision Manufacturing Tolerances

To maintain stable performance at high frequencies, 1.85mm connectors feature extremely strict geometric tolerance control, ensuring contact alignment and consistency.

Compact Design

The compact dimensions of 1.85mm connectors make them suitable for high-density modules or test boards, helping reduce space requirements and enhance overall system integration.

Applications for 1.85mm Connectors

1.85mm connectors are widely used in the following industrial sectors.

Aerospace and Defense Systems

High-frequency systems like missile guidance, radar systems, and electronic warfare equipment demand exceptional signal stability and interference resistance. Due to their low loss and high reliability, 1.85mm connectors are extensively used in military radar modules, air-to-air communications, and high-frequency fire control systems.

Satellite Communications

In satellite ground stations and space communication equipment, 1.85mm connectors support high frequencies and low reflection characteristics, ensuring signal quality and stability during long-distance transmission. They are suitable for applications in the Ka band and above.

〈Extended reading:What is RF Microwave? Mastering Technology Applications and Key Components for More Stable Wireless Communication!〉

Millimeter Wave and 5G/6G Communication Technologies

As 5G and future 6G technologies transition into millimeter-wave bands (e.g., 28 GHz, 39 GHz, and beyond), 1.85mm connectors become critical interface components for developing and testing infrastructure equipment such as base stations and antenna array modules.

〈Extended reading:What is 5G Millimeter Wave? Key Differences and Features Over Regular 5G〉

High-Frequency Test and Measurement Equipment

Commonly found in test equipment like vector network analyzers (VNAs), spectrum analyzers, and signal generators. The high-frequency performance and mechanical stability of 1.85mm connectors ensure measurement accuracy and repeatability.

R&D and Laboratory Applications

During the development of high-frequency or ultra-wideband electronic components (e.g., millimeter-wave ICs, antennas, and modules), 1.85mm connectors provide stable test connections suitable for prototype validation, simulation testing, and research experiments.

Unmanned Vehicles and Sensing Systems

High-frequency applications like military drones, automotive radar, and border surveillance systems also utilize 1.85mm connectors to ensure interference-free signal transmission.

Precautions for Using 1.85mm Connectors

Prevent Dust and Contaminants from Contaminating Contact Surfaces

The contact surfaces of 1.85mm connectors are extremely precise. Even minute particles of dust, grease, or contaminants can cause increased signal reflection or poor contact.Example: In laboratory environments without clean, dust-free conditions, or during handling without gloves, connectors can easily accumulate microscopic particles. This leads to a sharp increase in VSWR and greater signal loss.

Use the Original Torque Wrench to Tighten Correctly

Over-tightening or under-tightening both impair 1.85mm connector performance. Loose connections may cause signal leakage, while excessive tightening risks damaging internal structures.

Example: Using a standard wrench to tighten arbitrarily may damage or deform contact surfaces, reducing the maximum usable frequency and causing signal attenuation.

Avoid Frequent Insertion/Removal to Prevent Contact Surface Wear

Repeated disassembly causes wear between the 1.85mm connector's center conductor and contact surface, degrading connection quality and lifespan.

Example: If a test device is plugged and unplugged multiple times daily, its VSWR performance may deteriorate significantly within weeks, affecting test results.

Use with Compatible Connectors; Avoid Forced Mating

1.85mm connectors are compatible with 2.4mm connectors but incompatible with SMA or 2.92mm connectors. Forcing non-compatible connectors may damage the interface.

Example: If a user mistakenly inserts an SMA connector into a 1.85mm female interface, it may cause the male interface to bend or even damage the tester's connector.

〈Extended reading:How to Choose the Right RP SMA Connector for High Frequency Projects?〉

〈Extended reading:SMA Connectors - The Most Common RF Connectors〉

Avoid Twisting or Bending the Cable Under Stress

Maintain appropriate bending angles for connectors and coaxial cables. Excessive bending (or sharp angles) can damage cables and connectors, impairing signal transmission.

Example: In a millimeter-wave test, limited bench space caused excessive cable bending, resulting in unstable signals and distortion.

Clean Regularly Using Specialized Cleaning Tools

Use dedicated cleaning wands, wipes, and isopropyl alcohol to clean contact surfaces, maintaining optimal connector performance.

Example: Laboratory test equipment undergoing regular maintenance maintains low reflection loss through cleaning procedures, ensuring accurate high-frequency measurements.

Comparison of 1.85mm Connectors with Other Connectors

When comparing high-frequency RF (radio frequency) connectors, 1.85mm connectors are specifically designed for extremely high-frequency (EHF) applications. They are commonly found in military, radar, 5G millimeter wave, advanced communications, or test equipment. Below is a detailed comparison table of 1.85mm connectors versus other common high-frequency connectors of SMA, 2.92mm, 1.0mm series.

〈Extended reading:SMA to K Connector Explained as the Key RF Component for High Frequency Technology〉

Comparison table of 1.85mm connectors and other connectors

|

Item |

SMA |

2.92mm (K) |

1.85mm (V) |

1.0mm (W) |

|---|---|---|---|---|

|

Connector Diameter |

Approx. 4.1 mm | Approx. 2.92 mm | Approx. 1.85 mm | Approx. 1.0 mm |

|

Frequency Range |

0 – 18 GHz (extended to 26.5 GHz for some models) | 0 – 40 GHz | 0 – 67 GHz | 0 – 110 GHz |

|

Impedance |

50 | 50 | 50 | 50 |

|

Connector Design |

Threaded | Threaded | Threaded, Precision Mating | Threaded, Ultra-Compact |

|

Application |

General RF Modules, Low-Frequency Communication | Test Instruments, High-Frequency Modules | Millimeter-wave communication, radar, precision test instruments (e.g., VNA) | Ultra-high frequency testing, chip packaging testing |

|

Compatibility |

Not fully compatible with RP-SMA | Incompatible with SMA | Partially compatible with 2.4mm connectors, but not interchangeable with SMA/2.92mm | Requires proprietary adapters; no universal compatibility |

|

Machanical Stability |

Good | Good | Excellent (precision alignment design) | Relatively fragile |

|

Cost |

Low | Moderate | Slightly above average (but cheaper than 1.0mm) |

High |

According to the comparison table, for applications operating between 40–67 GHz, 1.85mm connectors are one of the optimal choices. They outperform 2.92mm connectors in performance and offer higher reliability than 1.0mm connectors. In applications demanding high-frequency stability, precision testing, and robust mechanical strength (such as millimeter-wave radar, VNA instruments, and advanced communication modules), 1.85mm connectors become the mainstream choice. Their design balances high-frequency performance with mechanical durability, making them the preferred high-end connectors for 5G, satellite communications, and research institutions.

〈Extended reading:2.92mm Connectors -The High Frequency Applications for Microwave Field〉

Trusted 1.85mm Connector Manufacturer - Huang Liang Technologies

Huang Liang Technologies is a Taiwanese manufacturer specializing in high-frequency RF and microwave connectors. Its 1.85mm coaxial connector series delivers exceptional performance and reliability, finding extensive application in high-frequency domains such as military, aerospace, satellite communications, and millimeter-wave testing. Key advantages and features of Huang Liang Technologies' 1.85mm connectors include as below.

Ultra-high-frequency performance - Supports up to 67 GHz

Our 1.85mm connectors are engineered to support frequencies up to 67 GHz, making them ideal for high-frequency applications including millimeter-wave communications, radar systems, and satellite receivers.

Precision Mechanical Design - Ensures Impedance Consistency and Low Insertion Loss

Utilizing high-precision manufacturing techniques, these connectors guarantee 50Ω impedance consistency while delivering low insertion loss and excellent electrical performance, meeting the demands of high-frequency signal transmission.

Diverse Product Formats - Meet Various Application Needs

Offers multiple structural configurations, including straight, right-angle, flange, and panel types, and is compatible with 2.92mm connectors for enhanced system integration flexibility.

High-Reliability Material Selection - Enhanced Durability and Stability

Manufactured with high-quality materials to ensure durability and stability in demanding environments, suitable for long-term use and repeated mating cycles.

For detailed specifications, product catalogs, spec of 1.85mm connectors, or technical support regarding. Please visit our website at hltechmw.com. Alternatively, contact our sales team directly for professional consultation.

Conclusion

Overall, our 1.85mm connectors excel in high-frequency stability, precision, and product diversity, making them an ideal choice for millimeter-wave communication, radar testing, and high-frequency instrumentation systems. As a specialized manufacturer focused on RF and microwave connectors, Huang Liang Technologies possesses extensive R&D and production expertise. We offer one-stop services ranging from standard products to customized solutions, meeting diverse high-frequency application requirements. Should you have further interest in our products or require technical consultation and selection advice, please feel free to contact us. We will provide you with the most professional and timely support services.

〈Extended reading:Top 5 Key Indicators for Choosing the Right RF Company to Boost Performance〉