- HOME

- Applications

- Blog

- Microwave Coaxial Cables Design and Assembly for High-Frequency Communication

Microwave Coaxial Cables Design and Assembly for High-Frequency Communication

25-10-01

Microwave coaxial cables play a crucial role in modern high frequency communication and radio frequency systems. They serve as the bridge for signals transmitted from the transmitter to the receiver. Directly impacting the overall system's signal stability, transmission loss, and interference resistance. These high frequency cables are indispensable in 5G base stations, radar systems, satellite communications, and precision RF test instruments.

Through proper coaxial connector selection and assembly techniques, transmission efficiency can be enhanced while reflections and losses are minimized, ensuring stable high frequency signal performance over long distances and in complex environments.

This article will delve into the structure, performance characteristics, application domains, and design principles of microwave cable assemblies, empowering you to make more informed choices in RF design and system integration.

〈Extended Reading:Explore Microwave Frequency and Their Applications in RF Microwave Connectors〉

Role of Microwave Cable Assemblies

Within a complete microwave cable assembly, microwave coaxial cables act as the core transmission element, determining the overall assembly's performance stability as well as transmission efficiency. Key Functions of microwave coaxial cables in microwave cable assemblies are as below.

Handling High Frequency Signal Transmission

Microwave coaxial cables transmit high frequency RF or microwave signals between connected devices (e.g. test instruments and antennas, modules and amplifiers). Their electrical performance directly impacts the system's signal integrity and low-loss characteristics.

〈Extended Reading:What Is High Frequency? High Frequency Features and Applications!〉

Determining the Frequency and Insertion Loss of the Components

Based on the structure (e.g. conductor size, insulation layer, shielding method) and materials (e.g. PTFE, silver-plated copper, braided shielding) of microwave coaxial cables, that determine critical metrics for microwave cable assemblies. Including in frequency operating range, insertion loss, and reflection loss.

Impact on Mechanical Flexibility and Durability

Beyond electrical properties, microwave coaxial cables also influence a component's flexibility, resistance to bending fatigue, high temperature tolerance, and corrosion resistance. These mechanical characteristics are critical for applications requiring bendability, repeated mating cycles, or exposure to harsh environments.

Design Trends in Microwave Coaxial Cables

Microwave coaxial cable design continues to evolve as high frequency applications like wireless communications, 5G, satellite navigation, and military radar mature. The focus is no longer solely on signal transmission but on maintaining performance under high frequency, high-speed, high-stability conditions and in extreme environments. Several current design trends are included as follow.

〈Extended Reading:Understanding Hermetic Sealing Technology and Hermetic Connectors in RF Applications〉

Lower Insertion Loss and Higher Frequency Support

By utilizing advanced low-dielectric-constant insulation materials (such as high-grade PTFE, ePTFE, or LCP), signal attenuation can be effectively reduced. This enables microwave coaxial cables to support frequencies up to 40 GHz or higher while maintaining low insertion loss.

Miniaturization and Ultra-Flexible Design

In space-constrained applications (e.g. satellite modules, radar antenna arrays), demand has driven the design of microwave coaxial cables with finer diameters and greater flexibility while retaining high frequency performance, such as .047 and .086 ultra-fine coaxial cables.

Enhanced Mechanical and Environmental Resistance

Microwave coaxial cables incorporate multi-layer braided shielding or metal foil designs to enhance EMI resistance and mechanical fatigue endurance, extending service life in harsh environments (e.g. high temperatures, vibration, and salt spray).

Modular and Plug-to-Use Components

Microwave cable assemblies are increasingly adopting "modular and standardized" designs, facilitating rapid on-site installation, replacement, or maintenance while reducing overall system assembly and testing time.

How do Microwave Coaxial Cables Adapt to Extreme Environments?

Microwave coaxial cables must endure prolonged exposure to extreme conditions including high and low temperatures, intense vibration, salt fog corrosion, or high humidity in many high-end applications such as aerospace, military radar, maritime communications, outdoor 5G base stations, as well as industrial automation. To ensure stable system operation and signal quality, microwave coaxial cable designs must incorporate to the following countermeasures.

〈Extended Reading:What is 5G Millimeter Wave? Key Differences and Features Over Regular 5G〉

Material Selection with Superior Environmental Resistance

-

Outer Jacket:Utilize materials with high temperature resistance, UV resistance, and chemical corrosion resistance, such as FEP, PFA, Teflon, or weather-resistant polyurethane (PUR).

-

Inner Conductor and Contact:Employ materials like silver-plated copper or gold-plated beryllium copper to resist oxidation and maintain excellent conductivity.

-

Insulator:Employ PTFE or ePTFE, capable of withstanding temperature variations from -55°C to +200°C while maintaining stable dielectric constants.

Structural Design Enhances Earthquake-Resistant and Stability

-

Multi-layer Shielding Structure:Microwave coaxial cables incorporate dual shielding layers of braided copper and aluminum foil, enhancing EMI (electromagnetic interference) resistance and vibration tolerance.

-

Flexible or Semi-Rigid Construction:For applications involving severe vibration or frequent bending. Flexible designs prevent cable fatigue failure.

-

Reinforced Connector Fixing:Incorporating anti-vibration washers, epoxy encapsulation, or laser soldering during assembly enhances overall resistance to mechanical impact.

Process and Testing for Consistent Quality Assurance

-

Salt Spray Test:Simulates marine or high-humidity environments to evaluate corrosion resistance.

-

Thermal Cycling Test:Validates electrical continuity stability and material structural integrity under extreme temperature variations.

-

Mechanical Tensile and Bending Testing:Evaluates cable durability under actual operating conditions.

What Are the Differences and Selection Criteria for Microwave Coaxial Cables?

The main differences are structural materials, electrical characteristics, mechanical strength, and environmental tolerance when selecting microwave coaxial cables. For instance, frequency range, insertion loss, flexibility, and bending life will influence the selection of microwave coaxial cables according to actual application requirements.

The following is based on several representative microwave coaxial cables introduced on the official website of Huang Liang Technologies.

〈Extended Reading:Microwave Communication: The Core Technology of Modern Technology and the Key Role of RF Connectors〉

Low Loss Flexible Cable

-

Structural Characteristics:Microwave coaxial cables typically feature dual-layer shielding (braided + foil) combined with low-dielectric-constant foam polyethylene insulator.

-

Electrical Performance:Low insertion loss, typically operating at frequencies up to 18 GHz or higher.

-

Applications:RF test equipment, communication base stations, and indoor system connections.

-

Features:Flexible and bendable, easy to install. Suitable for locations requiring frequent installation or with limited space.

Semi-Rigid Cable

-

Structural Characteristics:Microwave coaxial cables feature a solid metal outer conductor (typically copper or aluminum tubing) that maintains its shape after being bent into a fixed form.

-

Electrical Performance:Stable impedance, extremely low loss, excellent VSWR performance, suitable for high frequencies (up to 26.5 GHz and beyond).

-

Applications:Satellite systems, military communication modules, and precision test equipment.

-

Features:Provides high stability and excellent interference resistance. Suitable for fixed wiring in harsh environments.

Conformable Cable

-

Structural Characteristics:Outer conductor features a flexible metal structure with moderate conformability, but less rigid than semi-rigid cables.

-

Electrical Performance:Superior insertion loss and VSWR performance compared to standard flexible cables.

-

Applications:Used in RF modules requiring simple bending and fixed routing.

-

Features:A compromise solution between flexible and semi-rigid cables.

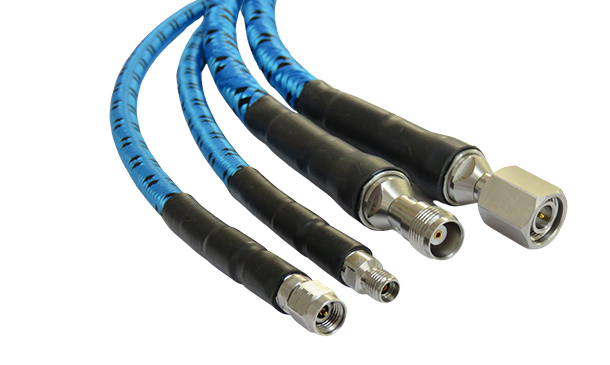

〈Product Recommendations: RF Cable Assembly〉

High Frequency Cable (HF Cable)

-

Structural Characteristics:High-quality multi-layer shielding design with PTFE or ePTFE insulator.

-

Electrical Performance:Supports frequencies up to 40 GHz or higher, with extremely low insertion loss and excellent VSWR.

-

Applications:High-speed data links, millimeter-wave radar, and millimeter-wave modules.

-

Features:Ideal for high frequency, high-speed applications. Commonly paired with high frequency connectors such as 2.92mm and 2.4mm.

Microwave Cable Assembly Matching Techniques

Selecting appropriate components and pairing them effectively when designing and assembling microwave cable assemblies. It is not only reduces signal loss but also enhances overall interference resistance and long-term stability. Below are practical pairing techniques and recommendations.

Key Considerations for Microwave Coaxial Cables

-

Frequency Matching:Select cables based on application frequency. For example, RG-type low-loss cables are suitable for frequencies below 18GHz. While PTFE cables or low-loss semi-rigid cables designed for high frequencies are recommended for frequencies above 26.5GHz.

-

Dielectric Material Selection:Microwave coaxial cables utilize PTFE, ePTFE, or low-dielectric-loss materials to stabilize transmission and reduce insertion loss.

-

Structural Considerations:Flexible cables are recommended for dynamic applications. Semi-rigid or low-profile designs are suitable for fixed installations or measurement systems.

〈Extended Reading:RF Cables Major Characteristics, Applications and Key Points for Selection〉

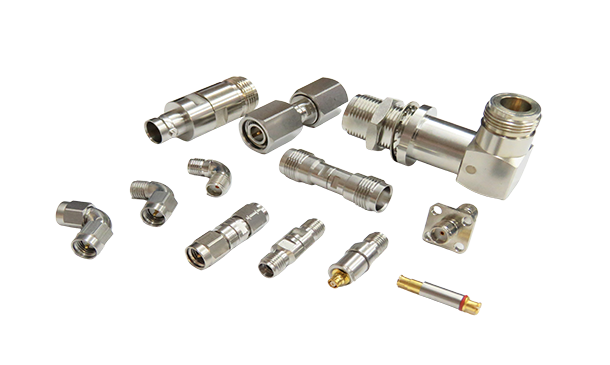

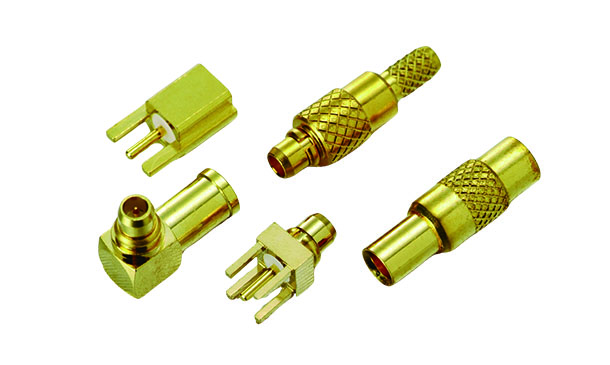

Connector Selection Recommendations

-

Impedance Matching:Ensure all connectors have consistent impedance (e.g. 50Ω) to prevent increased VSWR.

-

Connector Selection:For high frequency applications, using high frequency connectors such as SMA, 2.92mm, or 2.4mm.

-

Termination:Select precision crimping, soldering, or mechanical fastening based on application strength and environmental conditions.

〈Product Recommendations: RF Connector Products〉

Connector Processing and Mechanical Strength Reinforcement

-

360-degree shielded soldering or crimping:Enhances EMI interference resistance.

-

Reinforced cover fixation:Prevents internal damage from tension or bending.

-

Install strain relief boots:Reduces risk of connector damage from stress concentration.

Overall Assembly Quality and Testing Recommendations

-

Factory-level full inspection testing:Includes VSWR, insertion loss, time domain reflectometry (TDR), and other tests.

-

Full shielding design:Complete grounding of inner/outer conductors and terminals effectively reduces noise and crosstalk interference.

-

Manufacture consistency:Utilizing automated crimping and mass production processes helps control batch-to-batch consistency and repeatability.

How to Select a Microwave Coaxial Cable Supplier?

Besides basic pricing considerations, evaluation should encompass multiple critical aspects to ensure product quality and long-term partnership benefits when selecting a supplier of microwave coaxial cables. Below are recommended criteria for choosing a quality supplier, along with corresponding advantages of Huang Liang Technologies.

Product Quality and Reliability

-

Importance of Selection:Microwave applications demand exceptionally high signal transmission standards, where quality stability directly impacts system performance. Pay particular attention to microwave coaxial cables' performance metrics such as insertion loss, return loss, VSWR, and shielding effectiveness.

-

Advantages of Huang Liang Technologies:All microwave coaxial cables are qualified from undergo rigorous inspection and high frequency testing. We offer material selections tailored to application needs, including high frequency low-loss, environmentally resistant, and highly stable options.

Technical Integration and Customization Capabilities

-

Importance of Selection:Each field has specific requirements for microwave coaxial cables in terms of length, frequency support, and radius bend from different applications such as aerospace, 5G, and military. Suppliers must possess customization and system integration capabilities.

-

Advantages of Huang Liang Technologies:We possess in-house production and design teams, enabling us to provide complete microwave cable assembly solutions tailored to customer requirements. We assist in designing optimal configurations and performance specifications.

Professional Certifications and Quality Assurance System

-

Importance of Selection:International applications typically require compliance with certification standards (e.g. ISO 9001, ROHS, and MIL-STD), which also serve as benchmarks for evaluating quality management.

-

Advantages of Huang Liang Technologies:We hold ISO, AS9100 quality system certification as well as we can provide components and reports compliant with international standards like MIL, IEC, and REACH upon request.

Stable Delivery Times and Flexible Coordination

-

Importance of Selection:Addressing installation, testing, and maintenance issues serves as a critical backbone for ensuring system operation.

-

Advantages of Huang Liang Technologies:We offer comprehensive support including cable selection consultation, assembly recommendations, connector layout design, test report analysis, and dedicated after-sales service in person.

Conclusion

As RF and microwave technologies continue to evolve, demands for the performance and stability of microwave coaxial cables and microwave cable assemblies grow increasingly stringent. Every stage from design and material selection to assembly impacts signal quality and system reliability. Therefore, selecting a partner with professional expertise is crucial to ensuring product performance and longevity.

Huang Liang Technologies offers a comprehensive product line and years of practical experience as a leading Taiwanese manufacturer of RF microwave connectors and microwave cable assemblies. We provide high quality microwave connectors, adapters, coaxial cables, and customized assemblies widely used in communications, aerospace, defense, industrial control, and other fields. We also provide technical consultation and selection guidance to help customers develop the most suitable high frequency solutions. If you have any questions regarding product specifications, application requirements, or technical support, please feel free to contact us at any time. We will assist you in mastering every high frequency challenge with our most professional service.

〈Extended Reading:SMA to K Connector Explained as the Key RF Component for High Frequency Technology〉