- HOME

- Applications

- Blog

- Understanding Hermetic Sealing Technology and Hermetic Connectors in RF Applications

Understanding Hermetic Sealing Technology and Hermetic Connectors in RF Applications

24-07-31.png)

Hermetic sealing technology is a technology designed to maintain a tight seal when connecting electronic devices and to ensure that the internal environment of the connected device is not affected by the external environment. Hermetic sealing connectors are typically used in applications that require water, dust or corrosion resistance.

What is hermetic sealing technology?

Hermetic sealing technology refers to the sealing methods used in the manufacture of electronic, mechanical, and optical components that effectively prevent the ingress of air and water. The term "Hermetic" is derived from the Greek myth of Hermes. It emphasizes the sealing of these components against the environment.

Importance of Sealing Technology

Protection of Internal Components

Sealing technology effectively prevents air, moisture, chemicals or other contaminants from entering the interior of the connector. This is essential to protect the internal electronic components and contact points from external contamination that could cause electrical degradation or serious malfunction.

Improving Reliability

In applications where high reliability is required, such as aerospace, medical equipment, military systems, etc., sealed connectors ensure that the system will operate under extreme conditions, unaffected by the external environment.

Prevents Corrosion and Oxidation

Metal seals are usually welded or encapsulated in a vacuum or inert gas environment during the manufacturing process, thus preventing oxidation and corrosion of metal surfaces. This ensures the stability and durability of the seal.

Wide Range of Applications

Sealed connectors are used in a wide range of applications requiring a high degree of protection and environmental control, including submarine cables, oil and gas pipelines, battlefield communications, mars rovers, and other requests in extreme conditions.

Key Points of Sealing Technology

Sealing Material

Seals are usually made using metals such as aluminum, copper or stainless steel. These materials are chosen for their corrosion resistance and ability to maintain integrity over time.

Sealing Process

The sealing process involves heating metal parts to high temperatures under controlled conditions, usually in a vacuum or inert gas environment. This also ensures that the metal surfaces are effectively bonded together without any contamination or oxidation to form a tight seal.

Applications of Sealing Technology

Sealing technology is critical in industries that need to protect the internal environment of electronic or sensitive equipment. For example, it is used in semiconductor packaging, aerospace components, medical equipment and some types of sensors.

Advantages of Sealing Technology

The main advantage of sealing technology is the ability to provide long-term protection against moisture, gases and other contaminants. This helps to maintain the reliability and performance of the sealing element, especially in harsh or unpredictable environments.

Progress of Sealing Technology

Over time, advances in materials science and manufacturing technology have improved sealing technology. This includes the development of laser welding technology to provide precise and clean seals, as well as the use of advanced coatings to enhance the durability of seals.

The Importance of Glass Beads in Sealing Technology

Precise Seal Formation

Glass beads are manufactured to very precise dimensions, which allows them to effectively fill gaps and irregularities in sealing applications. This precision ensures a tight and consistent seal, thereby minimizing the risk of leaks or the ingress of contaminants such as water, dust or gas.

Environmental Resistance Factors

Glass beads are made of high purity glass with excellent resistance to corrosion, chemical reaction and thermal shock. This makes glass bead suitable for sealing requests in a variety of challenging environments, including marine, oil & gas, and electronic equipment.

Glass beads are an important component of sealing technology due to their precision, stability, resistance to environmental factors and versatility across a wide range of industrial applications. Glass beads are essential for reliable and durable sealing in critical equipment and systems, in order to increasing safety, performance and life cycle.

Features of Hermetic Connector

Airtight and Waterproof Seal

A key feature of sealed connectors is their ability to provide a complete seal against air, moisture, dust and other contaminants. This is achieved through precision engineering and sealing technology that prevents any leakage into or out of the connector.

Glass-to-metal sealing (GTMS) technology

Ensures consistent sealing performance under varying temperatures, pressures and environmental conditions.

High Reliability

Sealed connectors are known for their high reliability, maintaining electrical continuity and signal integrity even in challenging environments. Typically used in aerospace, defense, medical and industrial applications where reliability is critical.

Environmental Ratings

Sealed connectors meet stringent industry standards and environmental certifications, such as IP67 or IP68 ratings for waterproofing and MIL-STD for military applications.

Long Life Cycle

Due to its rugged construction and sealing capabilities, the sealing connector is designed for long-term use without degradation of performance. This long life cycle reduces maintenance requirements and ensures long term stability.

Sealed connectors are therefore an essential component in hermetically sealed environment applications for electronic signal transmission. Their functionality ensures reliable performance, durability and compliance with stringent environmental standards across a wide range of industries.

〈Extended reading:What are RF Connectors?〉

〈Extended reading:What is RF Microwave? Mastering Technology Applications and Key Components for More Stable Wireless Communication!〉

Hermetic Connectors Uses and Applications

Aerospace and Defense

Aircraft Systems: Sealed connectors are used in avionics and other aircraft systems to ensure reliability under extreme conditions, including high altitude and temperature changes.

Military Equipment: These connectors are used in military vehicles, weapons systems, and communications equipment to ensure that they remain operational in harsh environments.

〈Extended reading:SMA Connectors - The Most Common RF Connectors〉

Medical Equipment

Implantable Devices: Sealed connectors are used in pacemakers, cochlear implants, and other implantable medical devices to prevent body fluids from entering and damaging the electronic device.

Medical Imaging Equipment: These connectors are also used in MRI machines, CT scanners and other medical imaging equipment to maintain the integrity of sensitive electronic components.

Industrial Applications

Automation Systems: Sealed connectors are used in factory automation systems to protect electronic controls and sensors from dust, moisture and chemicals.

Harsh Environment Sensors: These connectors are ideal for sensors and instruments used in harsh industrial environments.

Telecommunications

Fiber Optic Network: Sealed connectors are used in the fiber optic network to ensure a stable connection that is not affected by environmental conditions.

Satellite Communications: In satellite communications, these connectors are critical to maintaining reliable connections in space, where exposure to vacuum and radiation is a problem.

〈Extended reading:What Is High Frequency? High Frequency Features and Applications!〉

Automobile

Electric and Hybrid Automobiles: Sealed connectors are used in electric and hybrid vehicles to protect sensitive electronic equipment from moisture, dirt, and extreme temperatures.

Engine Control Units: They are used in engine control units (ECUs) and other automotive electronics to ensure reliable operation.

Scientific Instruments

Space Exploration: Sealed connectors are essential for spacecraft and satellites to protect electronic systems from the vacuum and radiation of space.

Laboratory Equipment: These connectors are used in a variety of scientific instruments and laboratory equipment where maintaining a controlled environment is critical.

Key Benefits

- Environmental Protection: Provide airtight, moisture-proof sealing to protect sensitive electronic equipment.

- Reliability: Ensure the long-term reliability of the electronic connection under harsh environments.

- Durability: Designed to withstand extreme temperatures, pressures and corrosive conditions.

Materials and Design

Sealing connectors are usually made of materials such as stainless steel, Kovar, etc. that provide the necessary durability and resistance to environmental elements. Sealing is often accomplished using glass-to-metal seals or other advanced sealing technologies.

Overall, hermetically sealed connectors play a critical role in ensuring the performance and reliability of electronic systems across a wide range of industries by protecting them from harsh environmental conditions.

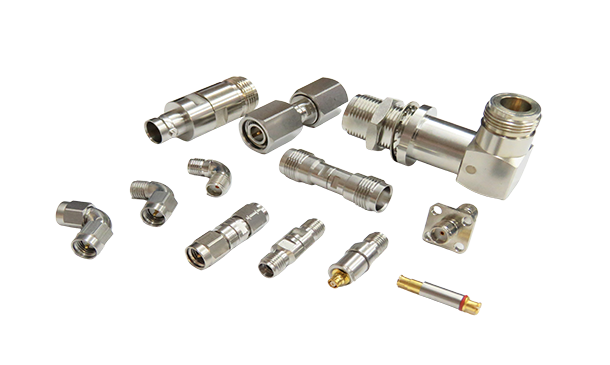

Recommended Hermetic Connectors Products

SMP ST. PLUG CONNECTOR SMOOTH BORE SOLDER-IN HERMETIC SHROUD FOR Ø.015 POST

The center pin and glass directly combined with the SMP body. It is SMP Smooth Bore Type. The end of the center pin is OD. .015.

〈Product Recommened: Part Number: 145-M983-25-9R〉

SMP ST. PLUG CONNECTOR FULL DETENT SOLDER- IN HERMETIC SHROUD FOR Ø.015 POST CONTACT

The center pin and glass directly combined with the SMP body. It is SMP full detent Type. The end of the center pin is OD. .015.

〈Product Recommened:Part Number: 745-M988-20-9Z〉

BMA ST. PLUG CONNECTOR FIELD REPLACEABLE 2 HOLE FLANGE WITH GLASS BEAD

This is a combination of BMA PLUG 2 HOLE FLANGE and Glass bead with center pin OD. .018.

〈Product Recommened:Part Number: 160-M44K/188(SD165)〉

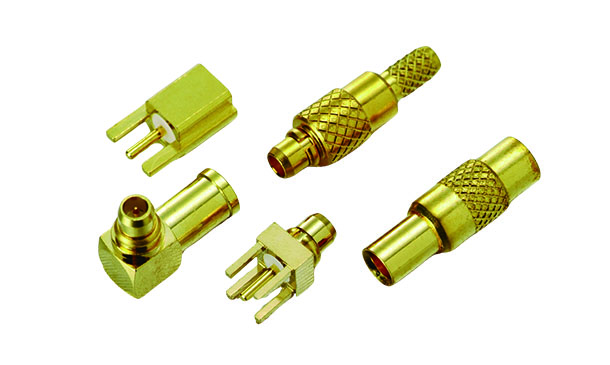

GLASS BEAD, Ø.020 PIN

This is an OD. .020 center pin glass bead that can be mated with a variety of interface connectors that accept Ø.020 pins.

〈Product Recommened:Part Number: 160-X010-20-9Z〉

GLASS BEAD, Ø.018 PIN

This is an OD. .018 center pin glass bead that can be mated with a variety of interface connectors that accept Ø.018 pins.

〈Product Recommened:Part Number: 101-X012-20-9Z〉

Conclusion

Our sealed connectors utilize glass-to-metal technology for a truly reliable seal. Typically specifies stainless steel or Kovar as its sealing product to provide an effective barrier against corrosion caused by gas ingress and dew point condensation. Gas-tight sealing technology prevents damage to sensitive electronic systems. Although moderately effective seals can be achieved by simple techniques such as epoxy resin potting, fused glass-to-metal seals are often necessary for high-pressure applications. Glass is an excellent insulator, adheres well to metal surfaces and is highly resistant to corrosion. Due to its strong mechanical strength and resistance to drastic changes in temperature and pressure, glass seals are extremely resistant to any rupture that might cause a leakage of the sealing package. Huang Liang Technology is a professional manufacturer of RF microwave connectors. The hermetically sealed product line offers a wide of standard and customized connectors to provide superior customer solutions. Please Contact Us for more information.