- HOME

- Applications

- Blog

- How Do Cable Assemblies Improve Signal Performance in High-Frequency Applications

How Do Cable Assemblies Improve Signal Performance in High-Frequency Applications

25-09-30

The demand of high frequency applications such as wireless communications, radar systems, satellite equipment, and 5G networks increasingly stringent requirements for signal integrity and stable transmission nowadays. Within these systems, cable assemblies play a critical role. Particularly at radio frequencies, even minor design flaws in cables or connectors especially an assembly can lead to signal loss, increased reflections, or overall degraded system performance. Therefore, selecting high quality, precision-engineered RF cable assemblies has become essential for ensuring stable high frequency signal transmission.

This article focuses on the applications and advantages of cable assemblies in RF systems, delving into how they enhance signal performance in high frequency environments. This includes technical aspects such as reducing loss, improving impedance consistency, and minimizing interference, further illustrating the core value of cable assemblies in modern high frequency technology.

〈Extended Reading:Explore Microwave Frequency and Their Applications in RF Microwave Connectors〉

What is a Cable Assembly? Functions and Applications

A cable assembly refers to the integration of a cable with one or more connectors, forming a ready-to-use cable module. These assemblies are configured according to application requirements, specifying length, connector types, shielding structures, and insulation materials to efficiently transmit power, data, or RF signals. Compared to general cables, cable assemblies undergo professional design and processing, delivering more stable and reliable electrical performance.

Within RF systems, cable assemblies play a key role, delivering main functions and value including as below.

〈Extended Reading:What is RF Microwave? Mastering Technology Applications and Key Components for More Stable Wireless Communication!〉

Stable Transmission of High Frequency Signals

High frequency signals are extremely sensitive to transmission paths. Cable assemblies are precisely engineered to effectively suppress signal attenuation and reflections at radio frequencies.

〈Extended Reading:What is 5G Millimeter Wave? Key Differences and Features Over Regular 5G〉

Ensuring Impedance Matching

Cable assemblies are typically designed for 50Ω impedance, though 75Ω designs occasionally occur. The primary goal is to ensure consistent impedance throughout the system, reducing VSWR and minimizing signal loss.

Electromagnetic Interference (EMI Shielding)

The multi-layer shielding design of cable assemblies significantly reduces electromagnetic interference from external environments, enhancing system signal integrity and reliability.

High Mechanical Reliability and Stability

RF systems often operate in harsh environments (high temperatures, high vibration). The robust structure of cable assemblies ensures long-term stable operation.

Modularity and Application Flexibility

Cable assemblies can be customized to different lengths and connector types (e.g., SMA, N-type, 2.92mm etc.) As required, offering high application flexibility for use in laboratories, measurement equipment, communication base stations, aerospace, and other fields.

What are the Components of a Cable Assembly?

A complete cable assembly usually comprises multiple key components, including wires/cables, connectors, terminals, and jackets. These elements work together to ensure optimal performance in electrical characteristics, mechanical strength, and environmental protection. Below is a detailed explanation of each component's function and importance.

Wire/Cable

-

Function:Serves as the core conductor of the cable assembly, responsible for transmitting power, data, or radio frequency signals.

-

Characteristics:Options include coaxial cable, twisted pair, or multi-core cable based on application requirements. Low-loss, impedance-stable coaxial cable is commonly used in RF applications.

-

Materials and Structure:Common conductors are copper or silver-plated copper. Insulation layers typically use materials like PTFE, PE, or FEP, offering excellent electrical properties and heat resistance.

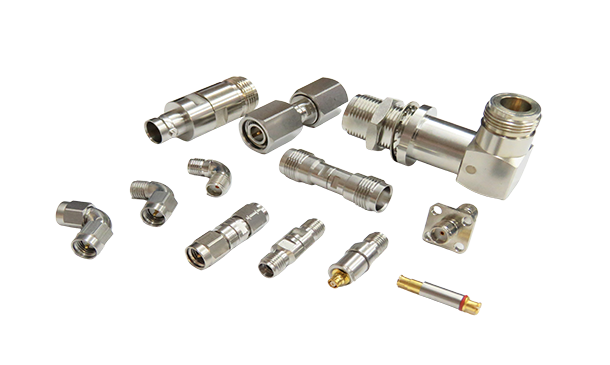

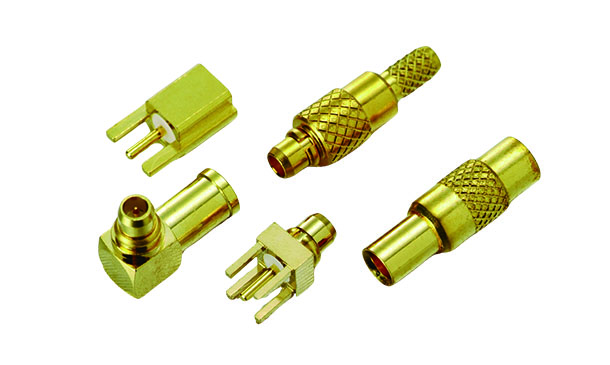

Connectors

-

Function:Provide a detachable and reliable electrical connection between cable assemblies and equipment.

-

Characteristics:Diverse connector types exist, such as SMA, N, BNC, 2.92mm, 3.5mm, and so on. Each suited for specific frequency ranges, power ratings, and environmental conditions.

-

Importance:High quality connectors maintain impedance matching and reduce signal reflection, making them a critical factor affecting performance in high frequency systems.

〈Product Recommendations: Connector〉

Terminals

-

Function:Provide fixed points or contact points for wire ends, commonly used for grounding, power supply, or input/output of specific control signals.

-

Applications:Particularly prevalent in automotive, industrial automation, and military systems, facilitating rapid connection and maintenance.

-

Types:Includes round terminals, spade terminals, blade terminals, etc., available in crimp or solder designs based on requirements.

Jacket

-

Function:Provides mechanical protection, insulation, and environmental sealing for cable assemblies, preventing damage from pulling, bending, friction, or liquid ingress.

-

Materials:Common materials include PVC, silicone, heat-shrink tubing, and nylon braided mesh, offering flexibility, heat resistance, flame retardant, or chemical corrosion resistance.

-

Importance:In demanding environments such as aerospace, military, and outdoor communications, jacket design is quite important that directly impacting overall durability and safety.

RF Cable Assemblies: Connecting Applications across Industries

RF Cable Assemblies, renowned for their superior high frequency signal transmission and interference resistance. They are widely adopted across industries demanding stringent signal quality. Key application areas include as following.

〈Extended Reading:Understanding Hermetic Sealing Technology and Hermetic Connectors in RF Applications〉

Telecommunications & Wireless Communication

Cable assemblies are used in base stations, antenna systems, 5G small cells, and other equipment. They ensure stable transmission of high frequency RF signals between different modules, enhancing overall network performance and reliability.

Aerospace

Cable assemblies are applied in satellite communications, aviation radar systems, flight instruments, and navigation systems. They must withstand high temperatures, intense vibrations, and high frequency operations, demanding exceptional shielding and mechanical strength from the cable components.

Military & Defense

Cable assemblies are used in tactical communication equipment, radars, missile control systems, and more. Emphasis is placed on weather resistance, electromagnetic interference (EMI shielding), and precision connections to meet stability and safety requirements in extreme environments.

Commercial Electronics

Includes high frequency electronic products such as test and measurement instruments, wireless devices, and RF modules. Cable assemblies are commonly found in R&D laboratories, measurement stations, and educational environments.

Industrial Automation

Used in machine communication modules, wireless control systems, and sensor data transmission. Cable assemblies support high frequency data transmission and real-time device communication requirements in smart manufacturing.

Medical Equipment

Specific applications include MRI, wireless monitoring devices, and RF energy therapy instruments. Cable assemblies require low signal loss and high reliability to ensure medical signals remain undistorted.

Custom RF Cable Assemblies Deliver Tailored Solutions to Meet your Exact Requirements!

Standard cable assemblies are widely used in general commercial or universal applications such as laboratory testing and basic communication equipment due to their uniform production specifications, plug-and-play functionality, and short lead times. They can meet basic high frequency signal transmission requirements. However, as application environments and technical specifications become increasingly diverse, a single standard product can no longer fully meet the demands of all application scenarios. In contrast, custom cable assemblies offer greater flexibility and functionality, making them particularly suitable for the following high-demand areas.

〈Extended Reading:What are RF Connectors?〉

High Frequency Applications

While operating frequencies exceed 10 GHz or reach millimeter wave (mmWave) levels, extremely high demands are placed on cable structural design, impedance precision, and connector matching. Custom designs can incorporate low-loss materials (such as PTFE dielectric), high-precision connectors, and optimized shielding structures to minimize insertion loss and reflections.

〈Extended Reading:What Is High Frequency? High Frequency Features and Applications!〉

High Precision Systems

Applications like communication measurement instruments, radar systems, or precision navigation systems demand absolutely stable signals and consistency.

Custom cable assemblies can be tailored for transmission length, electrical characteristics, and phase matching to enhance test and system reliability.

Harsh Environment Applications

Such as aerospace, military, marine equipment, or industrial sites, which often face conditions like high temperatures, humidity, salt fog, and vibration.

Custom cables can feature reinforced outer jackets, waterproof designs, chemical resistance, and mechanical durability which meet various military or industrial standards (e.g., MIL-SPEC, IP ratings).

Space-Constrained or Custom Routing

Within specific equipment, cable assemblies may require precise routing paths, avoidance of interference zones, or use of special bend radii. Customization allows adjustment of cable assembly length, connector orientation, and bend protection design, improving installation efficiency and aesthetics.

The RF Vision of Yours, Realized by Huang Liang Technologies

In today's increasingly sophisticated and diverse high frequency signal transmission landscape, selecting a reliable RF cable assembly supplier is not merely about purchasing products, but also crucial for ensuring system performance and quality. Huang Liang Technologies has deepened its expertise in RF connection technology for years, specializing in manufacturing high quality RF connectors, adapters and cable assemblies. We are committed to providing stable, reliable solutions for industries including communications, aerospace, defense, automation etc.

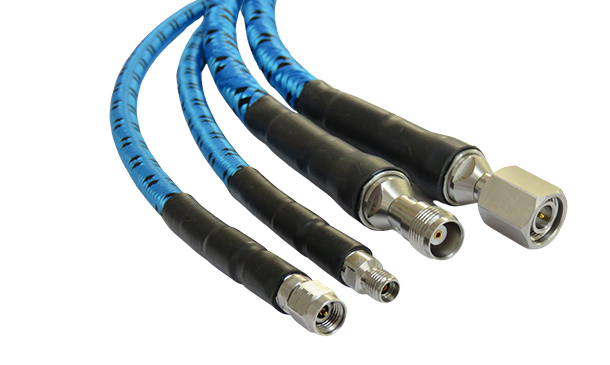

Core Features of our RF Cable Assemblies

High Frequency and Low-loss Design

-

Cable assembly utilizes high-performance coaxial cables and low-loss dielectric materials (e.g., PTFE insulation) to support applications up to 40GHz and beyond.

-

Precision impedance control design (50Ω) effectively reduces VSWR and insertion loss, enhancing signal stability.

Diverse Connector Options and Flexible Configuration

-

The cable assembly supports various RF connectors (e.g., SMA, N, 2.92mm, etc.) to meet different device interface requirements.

-

Customizable configurations, angled designs, and tailored lengths ensure assembly compatibility and optimized space utilization.

Stringent Quality Control and Testing

-

Each cable assembly undergoes comprehensive testing (including insertion loss, return loss, etc.) before shipment, meeting ISO and IPC international quality standards.

-

VSWR/S-parameter test reports are provided to ensure consistent high-frequency performance of cable assemblies.

Durable Design for Extreme Environments

-

Features reinforced shielding and high temperature and corrosion resistant jackets for demanding applications in military, aerospace, and industrial control sectors.

-

Supports IP-rated waterproof structures and reinforced bend-resistant designs.

Professional Customization Support Team

-

Huang Liang's RF product engineering team assists in designing optimal structural and technical specifications based on customers' requirements.

-

Flexible support for small-volume, diverse custom orders with short lead times.

Why choose Huang Liang Technologies as your RF cable assemblies supplier?

-

Technical Expertise:Years of focus on RF connector, adapter and cable assembly design as well as manufacturing, with deep understanding of high frequency application requirements and electrical structural characteristics.

-

Comprehensive Product Portfolio:One-stop supply from connectors and cable assemblies to finished product assembly, enhancing overall compatibility and supply stability.

-

Reliable Quality:Committed to Taiwanese manufacturing, every product undergoes rigorous testing. We have long-standing partnerships with major domestic and international business partners in communications, defense, and industrial control.

-

Flexibility and Efficiency:Strong customization capabilities enable rapid response from prototype development to mass production, shortening product development cycles.

〈Product Recommendations: All Product〉

〈Product Recommendations: RF Cable Assembly〉

Conclusion

In today's era of increasingly widespread high frequency applications, RF cable assemblies have become critical elements for ensuring signal quality, system performance, and overall stability. Whether in communications, aerospace, defense, or industrial automation, selecting suitable, high quality cable assemblies directly impacts the reliability and long-term performance of entire systems. While standard products offer convenience, customized solutions better address diverse demands when facing high frequency, high precision, and harsh environments.

For further details on product specifications, application recommendations, or customization services, please feel free to contact us. We are ready to provide the most professional technical support.

〈Extended Reading:Microwave Communication: The Core Technology of Modern Technology and the Key Role of RF Connectors〉